Ducati Diavel Service Manual: Adjusting of the air-gap phonic wheel sensor

(For front as well as rear sensor) in each case of maintenance that foresees:

- Replacement or refitting of the wheel

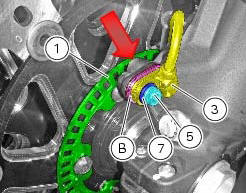

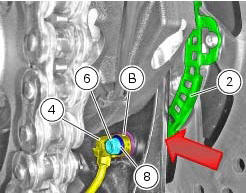

- Replacement or refitting of the phonic wheel (1) or (2)

- Replacement or refitting of the brake discs

- Replacement or refitting of the speed sensor (3) or (4)

- (Front) replacement or refitting of the sensor holder bracket

- (Rear) replacement or refitting of the calliper holder bracket

It is necessary to check the air-gap between the speed sensor and the phonic wheel, once the components are refitted.

Place the appropriate number of shims (b) under the abs sensor so as to achieve 1.3 To 1.9 Mm air-gap between abs sensor and phonic wheel. When shimming is correct, a 1.3 Mm feeler gauge will fit between abs sensor and phonic wheel, whereas a 1.9 Mm will not.

Check at three equally spaced locations (spaced about 120 apart) of the phonic wheels (1) and (2). Shims (b) come in two sizes: 0.2 Mm and 0.5 Mm. Combine the shims as required to achieve correct shimming.

When checking with the 1.3 Mm feeler gauge (go gauge) and the 1.9 Mm feeler gauge (no-go gauge), the abs sensors (3) and (4) must be firmly secured in their seats. This means you need to loosen and retighten the sensor retaining screw fully home with its washer each time you add or remove any shims.

Warning

For the front wheel abs sensor (3), total shims used must never exceed 3 mm on the base version and 3.7 Mm on the carbon version.

For the rear wheel abs sensor (4), total shims used must never exceed 3 mm.

After shimming, tighten the retaining screws (5) and (6) of the sensors (3) or (4) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings) placing washers (7) and (8) in-between and check again using the 1.3 Mm feeler gauge (go gauge) and the 1.9 Mm feeler gauge (no-go gauge).

Phonic wheels cleaning

It is important to check that both phonic wheels (21) and (20) are always clean.

Otherwise: gently remove any possible dirt deposits with a cloth or metal brush. Avoid using solvents, abrasives and air or water jets directly on the phonic wheel (21) or (20).

Bleeding of the abs hydraulic system

Bleeding of the abs hydraulic system

If some "sponginess" is detected on the brake control, due to air bubbles in

the system, bleed the system, as indicated in

sect. 4 - 3, Changing the brake fluid.

Before bleeding a brake pump, mo ...

Other materials:

Removing outer components

Note

The following removal operations are required in order to renew and/or

clean the crankcase halves. If the original

crankcase halves are to be reused, then the removal of these components is not

essential.

Unscrew the screw (17) and remove the oil breather valve (1) with the o-rings

...

Refitting the rear brake control

If the pushrod (18), clip (30) and fork (31) assembly has been dismantled,

reassemble it by screwing the nut (29) onto

the rod (18) and then screw the rod into the fork (31) to obtain the measurement

indicated in the figure.

Block the rod and tighten to a torque of 7.5 Nm +/- 10% (sect. 3 - ...

Overhaul of the crankcase halves

Carefully examine the engine crankcase halves.

Check that the surfaces of the crankcase halves are perfectly flat using a

reference surface.

Check that the bearings (1) and (18), and the bushings (2) and (17) are in

optimum conditions. Note that the main

bearings must always be changed in p ...