Ducati Diavel Service Manual: Adjusting the chain tension

Make the rear wheel turn until you find the position where chain is tightest. Set the vehicle on the side stand. Push down the chain at the point of measurement and release. Measure the distance between the "aperture" upper profile and pin centre.

The read distance must be: 9 to 11 mm.

Important

If the drive chain is too tight or too slack, adjust it so that tension reading will fall within specified range.

To adjust the tension remove the rear splash guard (sect. 7 - 13, Removal of the swingarm).

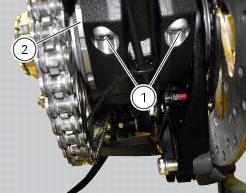

Slacken off the two clamp screws (1) that secure the rear wheel hub to the swingarm.

Fit the hook spanner code 88713.1038 Inserting its tooth in the eccentric hub (2).

Rotate the eccentric hub (2) to obtain the correct chain tension.

Turn counter clockwise to tighten the chain; clockwise to loosen (from chain side).

Important

An incorrectly tensioned chain will lead to accelerated wear of the transmission components.

If the screws (1) are removed, lubricate with specified grease underhead and thread, then tighten the screws (1) to the torque of 35 nm +/- 5% (sect. 3 - 3, Frame torque settings) proceeding with sequence 1-2-1.

Warning

The correct tightening of the fixing screws of the eccentric hub is essential for the safety of the rider and the passenger (sect. 3 - 3, Frame torque settings).

Refit the rear splash guard (sect. 7 - 13, Refitting the swingarm).

Adjusting the steering head bearings

Adjusting the steering head bearings

Excessive handlebar play or shaking forks in the steering head indicate that

the play in the steering head bearings

requires adjustment. Proceed as follows:

loosen the clamp screw (1) that holds t ...

Checking brake pad wear and changing brake pads

Checking brake pad wear and changing brake pads

Warning

Brake fluid is corrosive and will damage paintwork. Avoid contact

with eyes and skin. In the case of accidental contact,

wash the affected area thoroughly with plenty of running water.

Im ...

Other materials:

Flexible wiring/hoses positioning

The routing of the abs wiring has been optimised to ensure the minimum

obstruction.

Each section is designed to prevent interference with parts that might damage

wires or cause operating failures when

riding.

Table a

Table b

Table c

...

Removal of the front wheel

Support the bike so that the front wheel is raised from the ground.

Remove the front brake calliper (b) by unscrewing the two screws (a) securing

the calliper to the fork leg; do not

disconnect the calliper from the hose.

Warning

Do not operate the brake lever when the callipers are ...

Refitting the gearchange mechanism

Make sure that the gearchange linkage assembly (6) is installed with the ball

joint with a left-hand thread (a) facing the

lever (8).

Apply the recommended grease to the non-threaded surface of the pin (4).

Fit the first o-ring (5) in the pin (4).

Start the pin (4) in the gearchange leve ...