Ducati Diavel Service Manual: Adjusting the front fork

The front fork used on this motorcycle has rebound, compression and spring preload adjustment.

This adjustment is done using the outer adjusters:

- Rebound damping;

- Inner spring preload;

- Compression damping.

Park the motorcycle in a stable position on its side stand.

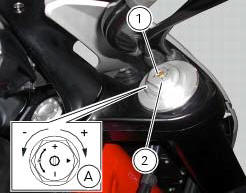

Turn the adjuster (1) on fork leg top with a flat screwdriver to adjust rebound damping.

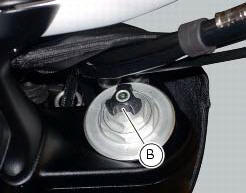

On the carbon model, adjustment is done using the knob (b) on the fork leg, without a screwdriver.

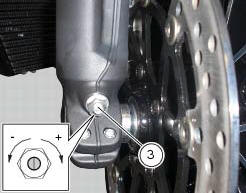

Turn the adjuster (3) on fork leg bottom with a flat screwdriver to adjust compression damping.

As you turn the adjusters (1) and (3), you will hear them click. Each click corresponds to different damping setting.

The stiffest damping setting is obtained with the adjuster turned fully clockwise to the "0" position. Starting from this position, turning counter clockwise, you can count the turns.

To change preload of the spring inside each fork leg, turn the hex. Adjuster (2) with a 22 mm hexagon wrench, starting from the fully open position (clockwise). From reference (a), every full turn clockwise corresponds to 1 mm of preload of the spring, up to a maximum of 15 mm, corresponding to 3 full turns.

Standard settings, from fully open position, are as follows: compression: 1 turn and a half; rebound: 1 and a half turns.

Spring preload: fully open (counter clockwise).

Important

Adjust both fork legs to same settings.

Adjusting the position of the gear change and rear brake pedals

Adjusting the position of the gear change and rear brake pedals

The position of the gear change and rear brake pedals in relation to the

footrests can be adjusted to suit the preferred

riding position.

To modify the gear change pedal position act in the foll ...

Adjusting the rear shock absorber

Adjusting the rear shock absorber

The adjuster (1) located on the lower connection holding the shock absorber

to the swingarm adjusts the damping during

the rebound phase (return).

The knob (2), located on the left side of the m ...

Other materials:

Adjusting the steering head bearings

Note

To adjust the steering bearing clearance, follow what is described in

sect. 4 - 3, Adjusting the steering head bearings.

If the problems found are not solved, check the wear of steering bearings (6)

and replace them, if necessary, as described

in paragraph "removal of the steering head c ...

How to turn the motorcycle off

To turn the motorcycle off, turn the switch from "run on" to "run off". The

engine stops. To switch the dashboard off,

push the on/off switch downwards. When released, the switch automatically

returns to the "run off" position.

Push the switch downwards to switch the engine off and enter " ...

Operating principle of dtc

The bbs receives the front and rear speed information from the abs over the

can. Then, the bbs sends the vehicle speed

information to be displayed on the dashboard over the can.

If the tangential speed of the rear wheel exceeds the tangential speed of the

front wheel by a given percentage, t ...