Ducati Diavel Service Manual: Adjusting the position of the gear change and rear brake pedals

The position of the gear change and rear brake pedals in relation to the footrests can be adjusted to suit the preferred riding position.

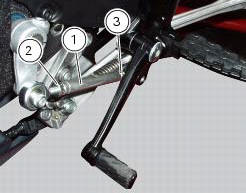

To modify the gear change pedal position act in the following mode: hold the linkage (1) and slacken the counter nuts (2) and (3).

Note

Nut (2) has a left-hand thread.

Fit an open-end wrench to hexagonal element of linkage (1) and rotate until setting pedal in the desired position.

Tighten both check nuts onto linkage.

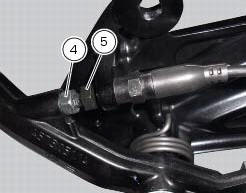

To adjust the position of the rear brake pedal, proceed as follows.

Loosen counter nut (4).

Turn pedal travel adjusting screw (5) until pedal is in the desired position.

Tighten the counter nut (4).

Work pedal by hand to make sure it has 1.5 - 2 Mm free play before brake begins to bite.

If not, check to modify the length of the cylinder push-rod in the following mode.

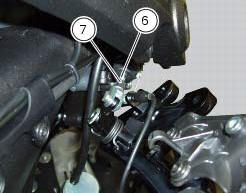

Slacken off the counter nut (7) on the pushrod.

Screw the rod into the fork (6) to increase play, or unscrew it to reduce play.

Tighten the counter nut (7) and recheck the pedal free play.

Adjusting the clutch lever and front brake lever

Adjusting the clutch lever and front brake lever

The clutch lever (1) is fitted with a span adjuster (2) which serves to alter

the distance of the lever from the handlebar.

The lever distance can be adjusted through 10 clicks of the dial (2). T ...

Adjusting the front fork

Adjusting the front fork

The front fork used on this motorcycle has rebound, compression and spring

preload adjustment.

This adjustment is done using the outer adjusters:

Rebound damping;

Inner spring preload;

Co ...

Other materials:

Removing the timing belt driveshaft pulleys

Use the tool code 88713.1805 To hold the driving pulley on the engine

crankcase against rotation.

Important

If this operation is carried out with the engine installed in the frame,

hold the driveshaft pulleys against rotation using the

tool code 88713.2011 Mounted on the alternator cover.

Lo ...

Engine speed-timing sensor

Introduction

The engine control system of the diavel is equipped with an inductive sensor

that allows the ecu to determine the speed

and timing phase of the engine. The sensor faces a phonic wheel with 48 teeth

minus 2.

The engine speed-timing sensor is an inductive sensor and faces a 48 ...

Checking the frame

Check the dimensions of the frame against the dimensions shown here to

determine whether it needs to be realigned or

renewed.

Important

Damaged frames must be changed, not repaired. Any work carried out on the

frame can give rise to potential danger,

infringing the requirements of ec directi ...