Ducati Diavel Service Manual: Adjusting the rear shock absorber

The adjuster (1) located on the lower connection holding the shock absorber to the swingarm adjusts the damping during the rebound phase (return).

The knob (2), located on the left side of the motorcycle, adjusts the preload of the shock absorber external spring.

Turn the adjuster (1) clockwise to increase damping h; or counter clockwise to reduce damping s.

Standard setting from the fully closed position (clockwise): -unscrew adjuster (1) by 8 clicks.

Spring preload: 15 mm.

The two nuts (2) on the upper part of the shock absorber serve to adjust the preload on the external spring. To change spring preload, slacken the upper locking ring nut. Then tighten or slacken the lower ring nut to increase or decrease spring preload.

Important

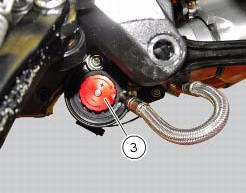

The knob (3) located on the expansion reservoir of the shock absorber adjusts the damping during the compression phase.

Turning the adjusters (1) or the knobs (2) and (3) clockwise to increase preload damping; they decrease turning them in the opposite direction.

Standard setting: from fully closed (clockwise) loosen: register (1) of 12 clicks; knob (2) fully open (counter clockwise); register (3) of 25 clicks.

Spring preload: 18 mm (max.18 Mm - min.25 Mm

Warning

The shock absorber is filled with high-pressure gas and can cause injuries if inexpertly dismantled.

Important

If the motorcycle is to be ridden with a pillion rider and luggage, we

recommend setting the rear shock absorber spring

preload to the maximum to ensure the best handling and proper ground clearance

at all times. It may also be necessary

to adjust the rebound damping accordingly.

Adjusting the front fork

Adjusting the front fork

The front fork used on this motorcycle has rebound, compression and spring

preload adjustment.

This adjustment is done using the outer adjusters:

Rebound damping;

Inner spring preload;

Co ...

Fairings

Fairings

...

Other materials:

Charging the battery

Before charging the battery, it is recommended to remove it

from the motorcycle.

Important

The battery is housed in the cowling, always contact

a ducati dealer or an authorised service centre for its

removal.

Remove the left cowling (1, fig. 137) Loosening:

side screw (2, fig. 137) Retaining ...

Adjusting the chain tension

Make the rear wheel turn until you find the position where chain is tightest.

Set the vehicle on the side stand. Push down

the chain at the point of measurement and release. Measure the distance between

the "aperture" upper profile and pin

centre.

The read distance must be: 9 to 11 mm.

...

Background setting function for the instrument panel on tank - dashboard 1

This function allows setting the "background" of the

instrument panel on tank.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"

" or (2, fig. 14) ?" " select the "back light" function

a ...