Ducati Diavel Service Manual: Air temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures air temperature. This sensor has a resistance of ntc type (negative temperature coefficient), that reduces its own value when the temperature increases. The air temperature sensor allows the engine control unit to modify the fuel-air mixture and ignition advance in relation to the atmospheric air temperature.

Components assembling position

The air temperature sensor is mounted on the right hand air intake (the image also shows the location of the connection).

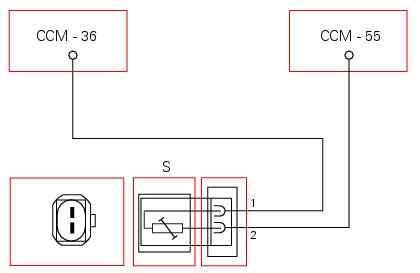

Wiring diagram

Ccm engine control connection, s air temperature sensor. 1 Green/blue - g/b, 2 black/purple - bk/v.

In the event of fault

In the event of an air temperature sensor fault, the engine control unit implements a recovery value of 25C.

Fault codes generated and possible correlated faults

Fault codes generated by the engine control unit and displayed by the dds (intake air temperature sensor diagnosis):

- Short circuit to vdc: check integrity of electric circuit and electrical connections.

- Short circuit to ground: check integrity of electric circuit and electrical connections.

- Open circuit: check integrity of electric circuit and electrical connections.

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

The dashboard service display shows the error "air temperature" and the eobd warning light activates.

Possible correlated faults: inadequate engine power, irregular idle speed (target idle speed is 1350 rpm with engine stabilised at operating temperature), the engine does not start easily. Check: -sensor resistance, which must be approximately 2 kohm at 25 C.

The air temperature value may be checked using the dds. Check that the value given is plausible.

If none of the aforementioned tests identify the problem and the air temperature sensor is in proper working order, replace the engine control unit.

Component replacement methods

No special measures are necessary in order to replace the air temperature sensor.

Component assembling position

Component assembling position

The throttle valve position sensor is integrated in the throttle valve

actuator motor.

Location of electric connection for throttle valve actuator motor - tps

(throttle valve position sen ...

Engine temperature sensor

Engine temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures the

temperature of the coolant (engine

temperature). This sensor has a resistance of ntc type (negative temperature ...

Other materials:

Key-on/key-off using the red key on the handlebar with the active key

A key-on can be performed by pressing the red key (6) on

the handlebar in the hands free on/off position and in

the presence of the active key (3, fig. 77).

Note

The active key (3, fig. 77) Has a range of approx. 1.5 M,

therefore it must be located within this range.

Key-off can be performed ...

Removal of the clutch transmission unit

Warning

The manufacturer of the clutch transmission unit (15) advises

against servicing of its internal parts due to the safetycritical

nature of this component.

Incorrect overhaul of these critical safety components can endanger rider and

passenger safety.

The only components that shoul ...

Rear wheel

Right-hand wheel nut

Washer

Spacer

Valve

Wheel

Circlip

Spare parts catalogue

Diavel abs front and rear wheels

Diavel carbon

abs

front and rear wheels

Important

Bold reference numbers in this section identify parts not shown in the

figures alongside the text, but which can ...