Ducati Diavel Service Manual: Alternator

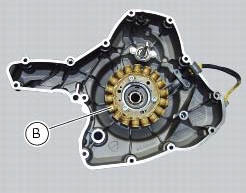

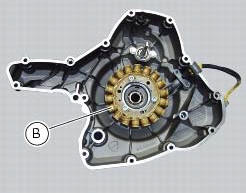

It is equipped with a 12 v, 430 w generator, consisting of a fixed element (stator, a) located on the generator cover and of a movable element (rotor, b) fixed to the crankshaft.

Note

To check the battery charging system for faults, use the dds diagnosis instrument and follow the instructions given in the paragraph, "testing the battery charging system" (sect. 6 - 11).

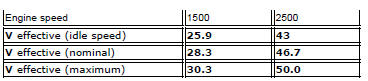

The absolute value of voltage measured across the terminals of two of the three yellow cables (the measured value will be the same whichever combination of cable is used) must be within the range indicated in the table below.

(Ambient temperature: 35 C - 70 C)

Important

Before testing, disconnect the alternator wiring from the electrical system when the ignition key is set to off.

Values significantly lower than those indicated above can be due to:

- Partially demagnetised rotor;

- Short-circuited windings.

In the above cases the whole alternator assembly (rotor and stator) should be renewed.

If checks have a favourable outcome, reconnect the alternator to the regulator with ignition key on off. Make sure that no cables are damaged or disconnected.

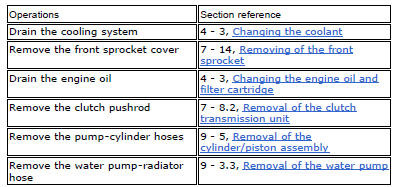

Removal of the alternator

Disconnect the cables of the alternator-side electric system (sect. 6 -1, Routing of wiring on frame).

Remove the generator cover, the stator (a) and the rotor (b) (sect. 9 - 8, Removal of the generator cover).

Refitting the

Refitting the generator

Fit the rotor (b), the stator (a) and the alternator-side crankcase cover.

Connect the cables of the generator side electric system (refer to the table in chapter "routing of wiring on frame", sect. 6 - 1).

Battery

Battery

Battery safety rules

Warning

Before carrying out any operations on the battery, keep in mind the

safety standards (sect. 1 - 3, General safety rules).

When under charge, batteries produce explo ...

Rectifier-regulator

Rectifier-regulator

The rectifier (1) is placed in the electrical components compartment.

The rectifier/regulator consists of an aluminium casing containing the diodes

that rectify the current produced by the

alter ...

Other materials:

Removal of the primary drive gear

Withdraw the clutch housing (1) complete with driven gear of the primary pair

(a).

Remove the inner spacer (2).

Remove the oil pump (d) (sect. 9 - 2.1, Removal of the oil pump).

Lock the primary pinion (b) with the holding tool 88713.3417 And loosen the

threaded ring nut (3) u ...

Charging the battery

Before charging the battery, it is recommended to remove it

from the motorcycle.

Important

The battery is housed in the cowling, always contact

a ducati dealer or an authorised service centre for its

removal.

Remove the left cowling (1, fig. 137) Loosening:

side screw (2, fig. 137) Retaining ...

The immobilizer system

For additional antitheft protection, the motorcycle is

equipped with an immobilizer, an electronic system that

locks the engine automatically whenever the ignition switch

is turned off.

The grip of each ignition key contains an electronic device

that modulates the output signal from a special ...