Ducati Diavel Service Manual: Battery

Battery safety rules

Warning

Before carrying out any operations on the battery, keep in mind the safety standards (sect. 1 - 3, General safety rules).

When under charge, batteries produce explosive gases. Keep batteries away from heat sources, sparks or open flames.

Instructions for use

The battery is a sealed, maintenance-free type and therefore requires no servicing installation.

Note

Always keep the battery clean. Apply grease around the battery terminal clamps to prevent corrosion.

Warning

Never remove the valve cover located on top of the cover. If the block, cover or terminals are broken or if the valve cover has been tampered with it is absolutely necessary to replace the battery.

Important

If the motorcycle is left unused for more than 30 days, remove the battery and store it in a safe, cool place.

Always charge the battery before the first operation and after long storage periods - such as before selling the vehicle.

Removal of the battery

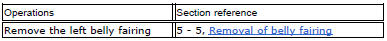

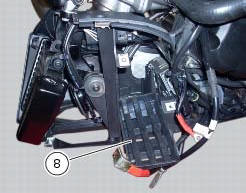

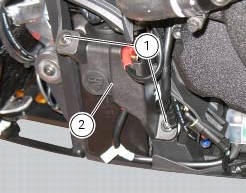

undo the screws (1) and remove the battery retaining bracket (2).

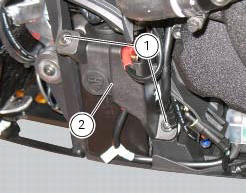

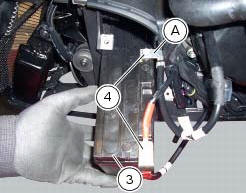

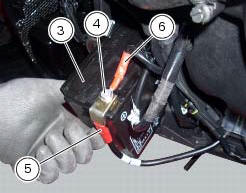

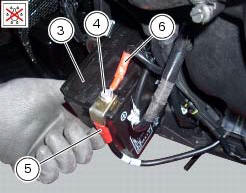

Slide out the battery (3) from its housing and, always starting from the negative terminal (-), loosen the screws (4).

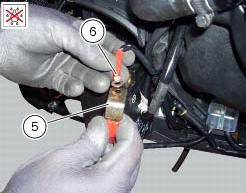

Remove the positive cable (5), the abs positive cable (6) from the positive terminal, and the negative cable (7) from the negative terminal.

Remove the battery drift (6) on the battery support (7).

Refitting the battery

Position the battery drift (6) on the battery support (7).

Place the battery (3) in its compartment by connecting first cable (7) to the negative terminal with the screw (4).

Connect the positive cable (5) and then the abs positive cable (6) to the positive terminal with the screw (4).

Tighten the terminal screws (4) to a torque of 10 nm +/- 10% (sect. 3 - 3Frame torque settings) and apply grease around the battery terminal clamps to prevent oxidation.

Place the battery (3) on its support, then position the retaining bracket (2) and tighten the screws (1) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Topping up the electrolyte

Topping up the electrolyte

Warning

Before carrying out any operations on the battery, keep in mind the

safety standards (sect.1 - 3, General safety rules).

The electrolyte in the battery is toxic and can cause burns if it ...

Alternator

Alternator

It is equipped with a 12 v, 430 w generator, consisting of a fixed element

(stator, a) located on the generator cover and

of a movable element (rotor, b) fixed to the crankshaft.

Note

To chec ...

Other materials:

Renewal of the cooling fan

Loosen the electro-fan retaining screws (15) and (17) and remove the

electro-fan (18) from the radiator.

Carry out the same procedure for the other radiator's electro-fan.

On refitting, position the coolant radiator fan (18) as shown on the fan support

(16), so that the three fan holes mat ...

Air temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures air

temperature. This sensor has a resistance of

ntc type (negative temperature coefficient), that reduces its own value when the

temperature increases. The air

temperature sensor allows the engine control unit t ...

Steering angle adjustment

Loosen the nuts (17) and adjuster screws (16) on both sides of the bottom

yoke.

Use a 6 to 6.5 Mm spacer (a) fitted to the fork outer tube, or use a gauge.

Turn the front forks to the right until the spacer (a) is seated against the

frame top tube.

Tighten the adjuster screw (16) to ...