Ducati Diavel Owners Manual: Beam setting

When checking beam setting, put the motorcycle upright.

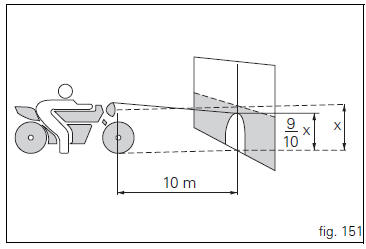

Tyres should be inflated at the correct pressure and one person should be sitting astride the motorcycle, keeping it at right angles to its longitudinal axis. Place the motorcycle opposite a wall or a screen, 10 meters apart from it, draw a horizontal line on the wall at the height of the centre of the headlight and a vertical one in line with the longitudinal axis of the motorcycle.

If possible, perform this check in dim light.

Switch on the low beam headlight.

The height of the upper limit between the dark area and the lit area must not be more than nine tenths of the height of the centre of the headlamp from the ground.

Note

Note

The procedure described here is in compliance with the italian standard establishing the maximum height of the light beam.

Owners in other countries should adapt this procedure to the regulations in force in the country where the motorcycle is used.

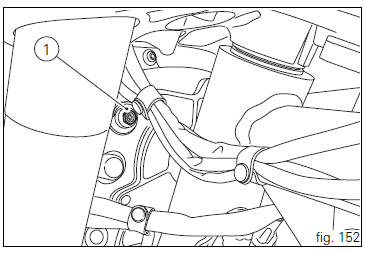

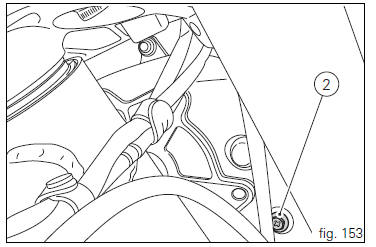

To adjust the headlight beam vertically, turn the screws (1), for horizontal adjustment, turn the screw (2).

Replacing the high and low beam bulbs

Replacing the high and low beam bulbs

Before replacing a burnt-out bulb, make sure that the new

bulb complies with the voltage and wattage specified in the

"wiring diagram", page 179. Always test the new bulb

before refitting ...

Rear-view mirror adjustment

Rear-view mirror adjustment

The rear-view mirror can be adjusted manually by pressing

points (a).

...

Other materials:

Headlight aim

The motorcycle must be perfectly upright with the tires inflated to the

correct pressure and with a rider seated, perfectly

perpendicular to the longitudinal axis.

Position the motorcycle 10 metres from a wall or a screen.

On the wall or surface, draw a horizontal line at the same height fr ...

Steering angle adjustment

Loosen the nuts (17) and adjuster screws (16) on both sides of the bottom

yoke.

Use a 6 to 6.5 Mm spacer (a) fitted to the fork outer tube, or use a gauge.

Turn the front forks to the right until the spacer (a) is seated against the

frame top tube.

Tighten the adjuster screw (16) to ...

General maintenance indications

Useful tips

Ducati recommends that you follow the instructions below in order to prevent

problems and obtain the best end result:

When diagnosing faults, primary consideration should always be given to

what the customer reports about motorcycle

operation since this information can highli ...