Ducati Diavel Service Manual: Changing and cleaning the air filters

The air filter must be replaced at the intervals described in the "scheduled maintenance chart" (sect. 4 - 2).

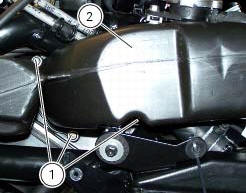

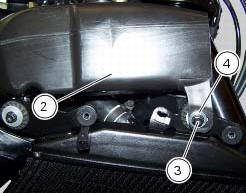

Work on the vehicle right side, loosen screws (1) that secure the intake duct (2) to the filter box, and the radiator retaining screw (3); recover the washer (4).

Remove the intake duct (2).

Pull out the filter cartridge (5) from the seat in the airbox.

The filter cartridge can be cleaned with a jet of compressed air or replace if necessary.

Important

A clogged air filter will reduce air intake and engine power, increase fuel consumption and cause a build up of deposits on the spark plugs. Do not use the motorcycle without a filter as impurities in the air could get into the engine and cause damage.

Properly refit the cartridge in the filter box housing.

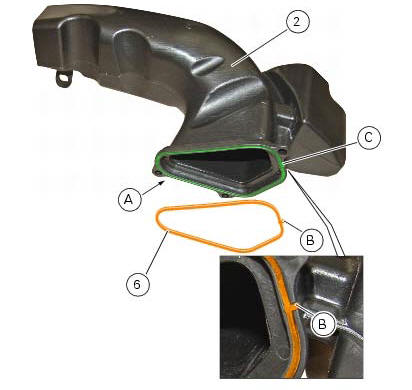

If the gasket (6) has been replaced, refit the new gasket in the proper seat (a) of the conveyor (2); place it so that the Tab (b) of the gasket (6) matches with slot (c) of the rh conveyor (2) as shown in the figure.

Note

Check for no abnormal wrinkles during gasket fitting.

Start the screws (1) and screw (3) with washer (4).

Tighten the screws (1) to a torque of 3.5 Nm +/- 10% (sect. 3 - 3Frame torque settings) and screw (3) to a torque of 10 nm +/-10% (sect. 3 - 3, Frame torque settings).

Important

If the motorcycle is used in very damp or dusty conditions, the air filter cartridge must be changed more frequently.

Check the air filter in the horizontal timing belt cover.

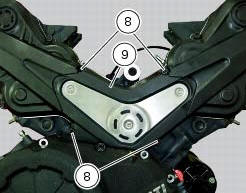

Loosen the screws (8) securing the central external cover (9) and remove it from the central side.

Loosen the screws (11) fixing the horizontal belt timing cover (7) and remove it from the horizontal cylinder assembly.

Loosen the screws (12) and remove the filter (10). Apply the recommended threadlocker to the screws (8) and (11).

Once the check has been carried out refit filter (10), screw without tightening the screws (12) and refit the horizontal timing belt cover (7) on the horizontal cylinder assembly by tightening the screws (11) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) for the plastic covers, and 6 nm (min. 5.5 Nm - max. 6.5 Nm) for the carbon ones (sect. 3 - 3, Engine torque settings).

Refit the central timing belt cover (9) by tightening the screws (8) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) for the plastic covers, and 6 nm (min. 5.5 Nm - max. 5.6 Nm) for the carbon ones (sect. 3 - 3, Engine torque settings).

Spark plugs replacement

Spark plugs replacement

Check the colour of the ceramic insulation around the central electrode:

an even, light brown colour indicates the engine is in good condition and

running at the right temperature.

Inspect the c ...

Checking the coolant level

Checking the coolant level

To the specified intervals in the "scheduled maintenance chart" (sect. 4 - 2)

Check the coolant level contained in

the expansion reservoir, on the right side of the vehicle.

The coolant level mu ...

Other materials:

Trip 1 meter

This function shows the distance travelled since the trip

meter was last reset (in km or miles depending on the

specific application).

Holding the button (1, fig. 14)

pressed for 3 seconds

when this function is displayed resets the trip meter.

When the reading exceeds 9999.9, Distance tr ...

Removing the valve rocker arms

With the cylinder head in the condition described in the previous paragraph,

remove the rocker arms.

Unscrew the eight plugs (12) and recover the seals (15).

Using an m6 screw, withdraw the shafts (2) of the opening rocker arms (3) on

the exhaust and intake sides.

Remove the openi ...

Warning indication (alarms/signals)

The instrument panel activates in real-time some warnings /

malfunction that are not dangerous for the correct operation

of the vehicle.

At key-on (at the end of the check) one or more "warnings"

are displayed if they are active.

When a "warning" is triggered, the indica ...