Ducati Diavel Service Manual: Changing bulbs

Changing the headlight bulbs

Before replacing a burnt out light bulb, ensure that the replacement bulb has the same voltage and power rating as specified for the lighting device in question (sect. 3 - 1.1, Lights/instrument panel).

Warning

The halogen light bulbs in the headlight become hot when switched on and remain hot for some time after they are switched off. Allow bulbs to cool before replacing them.

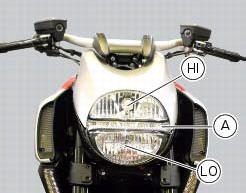

The position of the light bulbs in the headlight is as indicated below: low beam (lo), high beam (hi) and parking light (a).

Remove the headlight, as described in the paragraph "renewal of the headlight" of this section.

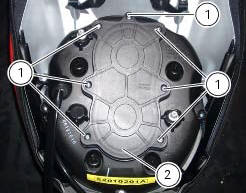

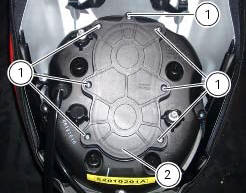

To access the headlight bulbs loosen the screws (1) and remove the cover (2).

High beam (hi)

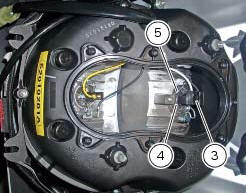

Disconnect the wiring connector (3) from the headlight bulb (4).

Release the retaining clip (5).

The bulb (4) has a bayonet base: press and twist counter clockwise to remove.

Fit the new bulb (4), insert the tabs on the bulb base into the corresponding slots to ensure the bulb is correctly positioned, push the bulb in and turn clockwise until it clicks into place.

Refit the connector (3) to the lamp (4), the cover (2) to the headlight, then tighten the screws (1).

Low beam (lo)

To change the lo beam headlight bulb (6) see the procedure described above for the hi beam headlight bulb.

Replace the lamp with a new one of the same type and rating (sect. 3 - 1.1, Lights/instrument panel).

Note

Do not touch the transparent part of the bulb with your fingers, this will darken it and cause a loss of brightness.

Renewal of the headlight

Renewal of the headlight

Disconnect the headlight connectors (a) from the main wiring (refer to the

tables of paragraph "routing of wiring on

frame", sect. 6 - 1).

Loosen nuts (2) that fix the front optical unit to th ...

Headlight aim

Headlight aim

The motorcycle must be perfectly upright with the tires inflated to the

correct pressure and with a rider seated, perfectly

perpendicular to the longitudinal axis.

Position the motorcycle 10 met ...

Other materials:

Engine start button

Introduction

The engine start button is located on the right hand handlebar switchgear set

and is used to turn the engine on.

Component assembling position

The engine start button is included in the switchgear set on the right hand

handlebar.

Location of right hand handlebar switchge ...

Lap registration function

This function describes the "lap" time registration.

If the function is activated (see "lap activation/deactivation description), the

lap time can be registered as follows:

pressing the flash headlight button (6) the first time starts the "lap timer"

for the first lap, and the dashboard show ...

Refitting the tail light

Fit the spacers with collar (3) into the rear vibration dampers (2) located

on the gloves compartment (23).

Note

Two spacers (3) must be inserted inside and outside on the right side and

two spacers (3) must be inserted inside and

outside on the left side.

Insert the split vibration damp ...