Ducati Diavel Service Manual: Changing the coolant

Warning

This operation must only be carried out when the engine is cold.

Attempting to change the coolant with the engine hot

could lead to burns from hot coolant or scalding steam.

Place a container under the engine and place the motorcycle on its side stand.

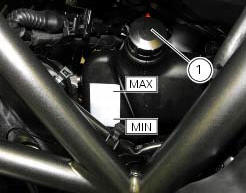

Remove the expansion reservoir filler cap (1).

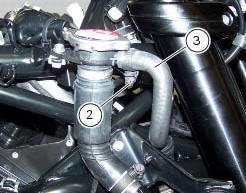

Loosen clip (2), disconnect the hose (3) and drain the coolant inside a container.

Loosen the cap (4) of the fluid exhaust hole placed on the pump cover.

Allow the coolant to drain off completely.

Screw plug (4) with a seal again in the fluid drain hole, and recover the new seal (5).

Tighten the plug (4) to a torque of 20 nm (min. 18 Nm - max. 22 Nm) (sect. 3 - 3, Engine torque settings).

Refill the circuit by pouring new coolant into the circuit via the remote filler cap (6).

Connect the pipe (3) by tightening the clamp (2) to a torque of 1 nm +/-10% (sect. 3 - 3, Frame torque settings).

Allow several minutes for the coolant to fill all the internal passages.

Start up the engine and allow the coolant to reach 110 C; run the engine for about 10 minutes.

Stop the engine and allow it to cool down so that all the air is expelled from the cooling circuit.

Warning

Keep your hands, clothing and tools well clear of the radiator fan at all times; this fan starts automatically without warning and could cause serious injury or damage.

Important

Check the cooling circuit for possible leaks.

Top up the coolant through the expansion reservoir filler to bring the level up to the max. Mark.

Tighten the cap (1) of the expansion reservoir.

Checking the coolant level

Checking the coolant level

To the specified intervals in the "scheduled maintenance chart" (sect. 4 - 2)

Check the coolant level contained in

the expansion reservoir, on the right side of the vehicle.

The coolant level mu ...

Changing the brake fluid

Changing the brake fluid

Warning

Brake fluid is corrosive and will damage paintwork. Avoid contact

with eyes and skin. In the case of accidental contact,

wash the affected area thoroughly with plenty of running water.

Ch ...

Other materials:

Warning indication (alarms/signals)

The instrument panel activates in real-time some warnings /

malfunction that are not dangerous for the correct operation

of the vehicle.

At key-on (at the end of the check) one or more "warnings"

are displayed if they are active.

When a "warning" is triggered, the indica ...

Checking and overhauling the components

Clearance between the clutch drum and friction plates

Insert a friction plate (e) in the clutch drum (f) and measure the clearance

(s) with a feeler gauge.

Clearance "s" must not exceed 0.6 Mm.

If it does, renew the plates and, if necessary, the clutch drum.

Overhaul of the clutch plat ...

Indicator air - air temperature

This function shows the external temperature.

Display limits: -39C - +124C

In the event of a sensor fault (-40C, +125C or disconnected), a string of

dashes "- - -" (not flashing) is displayed and

the "vehicle/engine diagnosis - eobd" light comes on.

Note

When the vehicle is stopped, the ...