Ducati Diavel Service Manual: Changing the engine oil and filter cartridge

Note

This operation has to be carried out with hot engine (but turned off) because the oil in these conditions is more fluid and its evacuation is faster and complete.

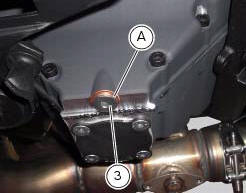

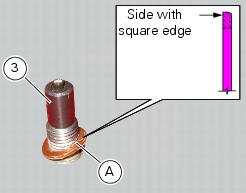

Remove the drain plug (3) with seal (a) from the oil sump and allow the oil to drain off.

Warning

Dispose of oil and/or filter cartridges in compliance with environmental protection regulations.

Remove any metallic deposits from the end of the magnetic drain plug (3). Clean the threads of the drain plug and apply three bond tb1215. Refit the drain plug complete with gasket (a) to the sump.

Position seal (a) so that the side with the square edge is facing the chain side crankcase half.

Tighten the exhaust plug (3) to a torque of 20 nm (min. 18 Nm - max. 22 Nm) (sect. 3 - 3, Engine torque settings).

Remove the oil sump filter cartridge (4) using service tool 88713.2906.

Important

Dispose of the used cartridge, do not attempt to reutilise it.

Fit a new cartridge (4), using the tool 88713.2906 Making sure to lubricate the gasket with engine oil.

Note

As an alternative, it is advisable to refill the filter cartridge with engine oil (4) before fitting it: this enables the recommended oil level to be maintained without topping up.

Screw the cartridge fully home and tighten it to a torque of 11 nm (min. 10 Nm - max. 12 Nm) (sect. 3 - 3, Engine torque settings).

Every two oil changes, clean the oil pickup gauze filter.

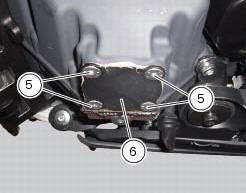

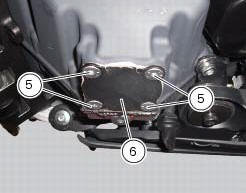

Undo the four screws (5) of the external cap (6) and remove it.

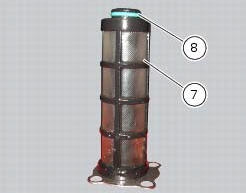

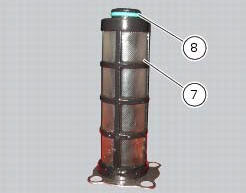

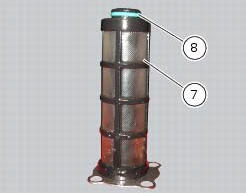

Remove the filtering element (7) and check the o-rings (8) and (9), replace them if necessary.

Clean the filter with petrol and compressed air. Take care not to damage the gauze.

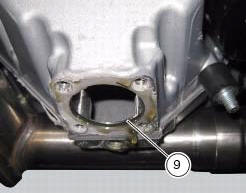

Place the o-ring (9) on the crankcase and the (8) one on the mesh filter (7).

Refit the mesh filter (7).

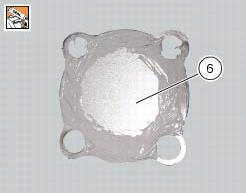

Apply a bead of fluid gasket to the cap (6) as shown in the figure.

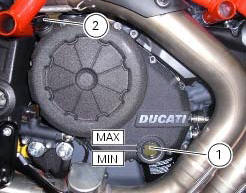

Remove the filler plug (2) and carry out refilling with the specified oil type (sect. 3 - 2, Fuel, lubricants and other fluids) up to reaching the notch that identifies the max level in the sight glass (1).

Refit the filler cap (2). Run the engine at idle speed for a few minutes.

Check that there are no oil leaks and that the engine oil pressure warning light on the dashboard switches off some seconds after starting up the engine. If not, switch off the engine and trace the fault.

After a few minutes, check that the oil level is the specified one; if necessary, restore the max. Level.

Tighten the external cap (6) retaining screws (5) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Check engine oil level

Check engine oil level

Check the engine oil level through the sight glass (1) on the right-hand side

of the oil sump.

Stop the engine and allow a few minutes for the oil to settle to a steady level.

Oil level must b ...

Checking valve clearances

Checking valve clearances

To check the valves clearance, it is necessary to have access to the cylinder

head covers and then remove the

components listed below.

Unscrew the two fixing screws (1) of the cover (2) accord ...

Other materials:

Checking and adjusting the valve clearances

Note

For clarity, the figures show the engine removed from the frame.

Move the piston of the cylinder being checked to tdc of the power stroke: in

this condition, all the valves are closed and

the timing shafts come in neutral position and, therefore, free to rotate; check

to the valve cl ...

Starter motor relay

Introduction

When the rider presses the start button, with all the safety conditions

required to enable engine start met, the engine

control unit enables the relay that activates the starter motor.

Component assembling position

Connection on starter motor relay.

Connection wiring diagram

...

Low battery level

The activation of this (amber yellow) "warning" indicates that the status of

the battery vehicle is low.

It is activated when the battery voltage is ¼ 11.0 Volt.

Note

In this case, ducati recommends charging the battery as soon as possible

with the specific device, as it is possible th ...