Ducati Diavel Owners Manual: Charging the battery

Before charging the battery, it is recommended to remove it from the motorcycle.

Important

Important

The battery is housed in the cowling, always contact a ducati dealer or an authorised service centre for its removal.

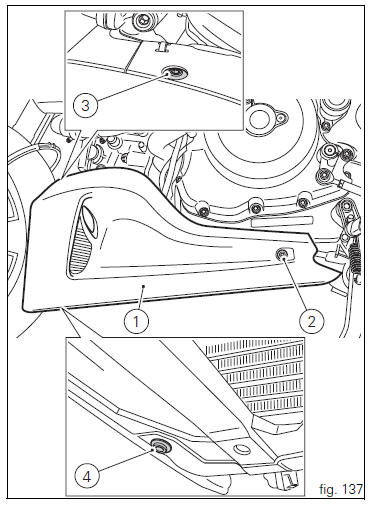

Remove the left cowling (1, fig. 137) Loosening: side screw (2, fig. 137) Retaining the electrical parts box; top screw (3, fig. 137) Retaining the electrical parts box; bottom screw (4, fig. 137) Retaining the central cowling;

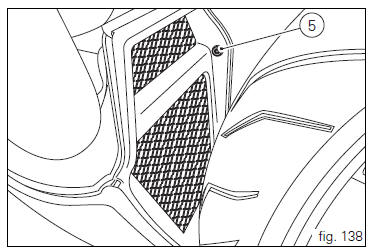

Screw (5, fig. 138) Retaining the central cowling to left cowling.

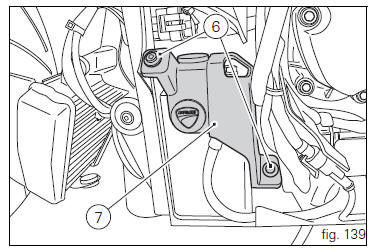

Unscrew the screws (6, fig. 139) And remove the battery mounting cover (7, fig. 139).

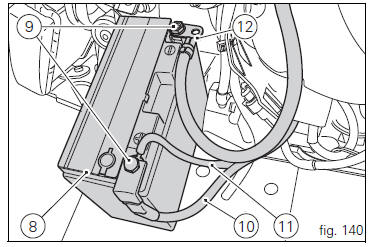

Slide out the battery (8, fig. 140) From its housing and, always starting from the negative terminal (-), loosen the screws (9, fig. 140).

Remove the positive cable (10, fig. 140), The abs positive cable (11, fig. 140) From the positive terminal and the negative cable (12, fig. 140) From the negative terminal.

Warning

Warning

The battery produces explosive gases: keep it away from heat sources and flames.

Warning

Warning

Keep the battery out of the reach of children.

Charge the battery at 0.9 A for 5÷10 hours.

Charge the battery in a well-ventilated area.

Connect the battery charger leads to the battery terminals: red to the positive terminal (+), black to the negative terminal (-).

Important

Important

Connect the battery to the charger before switching it on; failure to do so can result in sparking at the battery terminals, which could ignite the gases inside the cells.

Always connect the red positive terminal (+) first.

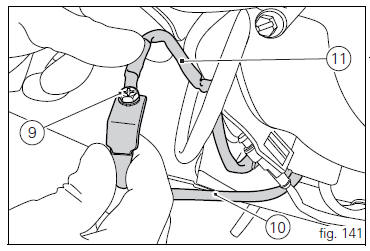

Lay down the abs positive cable (11, fig. 141), Onto positive cable (10, fig. 141) And start screw (9, fig. 141) In its thread on these cables.

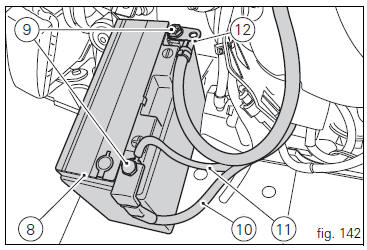

Connect the positive cable (10, fig. 142), Previously assembled to abs cable (11, fig. 142), To battery positive terminal, and negative cable (12, fig. 142) To battery negative terminal, by starting the other screw (9, fig. 142) In its thread.

Tighten the terminal clamp screws (9, fig. 142) To a torque of 5 nm ±10% and apply grease onto the battery terminals to prevent oxidation.

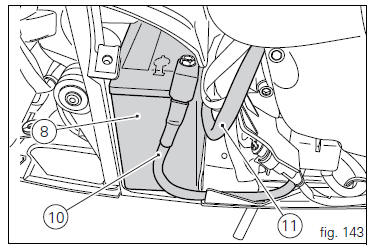

Reposition the battery (8, fig. 143) In the support, positioning the cables (10, fig. 143) And (11, fig. 143) As shown in fig.

143.

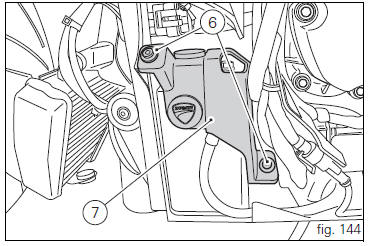

Refit battery mounting cover (7, fig. 144) And fasten tightening the screws (6, fig. 144) To a torque of 10 nm ±10%.

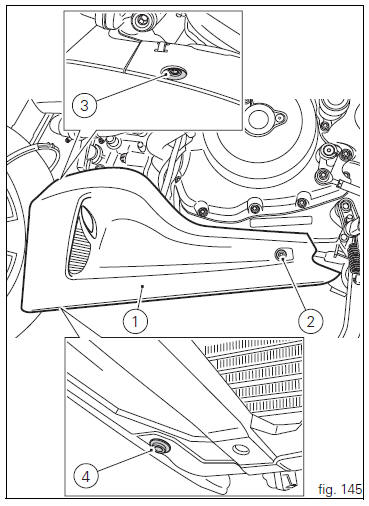

Refit the left cowling (1, fig. 145) As follows: start the side screw (2, fig. 145) Retaining the electrical parts box in its thread; start the top screw (3, fig. 145) Retaining the electrical parts box in its thread; start the bottom screw (4, fig. 145) Retaining the central cowling in its thread;

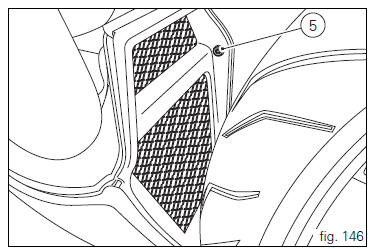

Start the screw (5, fig. 146) Retaining the central cowling to left cowling in its thread.

Tighten the screws (2, fig. 149), (3, Fig. 145), (4, Fig. 145) And (5, fig. 146) To a torque of 10 nm ±10%.

Adjusting throttle control free play

Adjusting throttle control free play

The throttle twistgrip must have free play of 1.5×2.0 Mm in

all steering positions, measured on the outer edge of the

twistgrip. If necessary, adjust it using the adjusters (1 and 2,

fig. 135 ...

Charging and maintenance of the battery during winter Storage

Charging and maintenance of the battery during winter Storage

Your motorcycle is equipped with a connector (1, fig. 147) To

which you can connect a special battery charger available

from our sales network.

...

Other materials:

Removal of the clutch transmission unit

Warning

The manufacturer of the clutch transmission unit (15) advises

against servicing of its internal parts due to the safetycritical

nature of this component.

Incorrect overhaul of these critical safety components can endanger rider and

passenger safety.

The only components that shoul ...

Fault indication

The dds (diagnosis ducati system) indicates all active errors and all

inactive but stored errors gathered by the bbs. A

simplified summary of the active errors is also shown in the master dashboard

service display when the dashboard is

switched on. Simultaneously, the eobd warning light is als ...

Refitting the steering head components

Important

The steering tube bearings (6) are identical but in no case may their

components be swapped around during reassembly.

Clean all contact surfaces and lubricate with the recommended grease.

To fit the external rings (c) of the bearings (6) to the steering tube, use the

tool with par ...