Ducati Diavel Service Manual: Checking and overhauling the components

Clearance between the clutch drum and friction plates

Insert a friction plate (e) in the clutch drum (f) and measure the clearance (s) with a feeler gauge.

Clearance "s" must not exceed 0.6 Mm.

If it does, renew the plates and, if necessary, the clutch drum.

Overhaul of the clutch plates

The clutch plates must not show any signs of blackening, grooves or deformation.

Measure the thickness of the friction plates; it should not be less than 2.6 Mm.

Important

The total thickness of the discs pack must not be less than 46.1 Mm.

Place the plate on a flat surface and check the amount of deformation with a feeler gauge.

Max. Flatness error: 0.2 Mm.

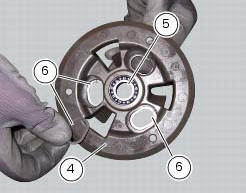

Overhaul of the pressure plate

Check bearing (5) condition; renew the bearing if the play is excessive.

Check the contact surfaces of the last friction plate; if extremely scored, polish it in the same manner as described previously for the cylinder head surface (sect. 9 - 4.5, Overhaul of cylinder head components).

Check conditions of the spring guide bucket tappet (g) of the pressure plate (4) and of the circlips (6).

Overhauling the pressure plate springs

Measure the length "l" of each spring (3).

Minimum length: 41 mm.

Renew any springs that are shorter than the above limit value.

Removal of the clutch

Removal of the clutch

Note

For clarity, the figures show the engine removed from the frame.

Undo the fixing screws (1) and remove the ring (2) and the springs (3) from

the pressure plate (4).

Slide the pre ...

Reassembling the clutch

Reassembling the clutch

Position the spacer (13).

Fit the flat ring (11) and the belleville washer (10) on the clutch center

(12), so that the convex side faces the clutch

drum.

Locate the belleville washer (8). ...

Other materials:

Removal of the expansion tank

Loosen the clamp (6), open the hose guide (a) and slide the hose (7) out of

the radiator.

Open clamps (14) and release the hoses that pass through them.

Loosen the screws (16).

Remove the tank (12) with its hoses (7) and (20) and the support (15).

Loosen the clamp (19) to r ...

Engine

Twin cylinder, four-stroke, 90 "l" type, longitudinal, with

deep sump die-cast crankcase.

Bore, mm: 106

Stroke, mm:

67.9

Total displacement, cu. Cm:

1198

Compression ratio:

11.5В±0.5:1

Max power at crankshaft (95/1/ec), kw/hp:

119 kw/162 hp at 9,500 rpm

Max torque at crankshaf ...

Recharging the battery

Examine the label on the battery showing the check intervals in order to

determine when to test the voltage.

Charge the battery if the open circuit voltage is lower than 12.8 V. Leaving

the battery discharged for more than one

month could damage it. Check the battery charge with a voltmete ...