Ducati Diavel Owners Manual: Checking brake and clutch fluid level

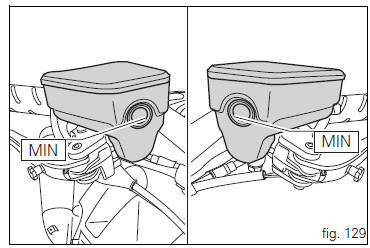

The levels should not fall below the min marks on the respective reservoirs.

If the level is too low, air can get into the circuit, thus impairing the efficiency of the system.

Brake and clutch fluid must be topped up and changed at the intervals specified in the scheduled maintenance table reported in the warranty booklet; please contact a ducati dealer or authorised service centre.

Important

Important

It is recommended all brake and clutch lines be changed every four years.

Brake system

If you find exceeding play on brake lever or pedal and brake pads are still in good condition, contact your ducati dealer or authorised service centre to have the system inspected and any air drained out of the circuit.

Warning

Warning

Brake and clutch fluid can damage paintwork and plastic parts, so avoid contact. Hydraulic fluid is corrosive and can cause damage and injuries. Never mix fluids of different qualities.

Check that the seals are in good condition.

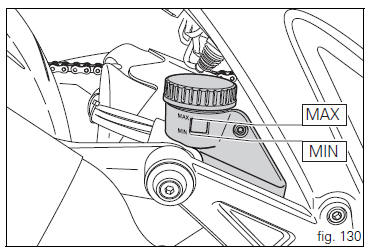

Clutch system

If the control lever has exceeding play and the transmission snatches or jams as you try to engage a gear, it means that there might be air in the circuit. Contact your ducati dealer or authorised service centre to have the system inspected and air drained out.

Warning

Warning

The clutch fluid level in the reservoir tends to rise as the friction material on the clutch plates wears out. Do not exceed the specified level (3 mm above the minimum level).

Checking and topping up coolant level

Checking and topping up coolant level

Check coolant level in the expansion tank on the right side of

the vehicle.

Steer the handlebar completely to the left and check that the

level is between the min and max marks on the side of the ...

Checking brake pads for wear

Checking brake pads for wear

Check brake pads wear through the inspection hole in the

callipers.

Change both pads if friction material thickness of even just

one pad is about 1 mm.

Warning

Friction material wear beyond th ...

Other materials:

Cleaning and replacing the spark plugs

Spark plugs are essential to smooth engine running and

should be checked at regular intervals.

The condition of the spark plugs provides a good indication of

how well the engine is running.

Have the spark plugs inspected or replaced at a ducati dealer

or authorised service centre; they will ...

Total distance covered indicator: "odometer"

This function shows the total distance covered by the vehicle

(in km or miles depending on the specific application).

At key-on the system automatically enters this function.

The odometer reading is stored permanently and cannot be

reset.

If the distance travelled exceeds 199999 km (or 19 ...

Disassembly of structural components and the frame

Before carrying out dimensional checks on the frame, you must remove all the

superstructures fitted, referring to the

removal procedures outlined in the sections of this manual.

The rear subframes (2) and (3) are structural components of the frame (1).

Both serve to support motorcycle super ...