Ducati Diavel Owners Manual: Checking engine oil level

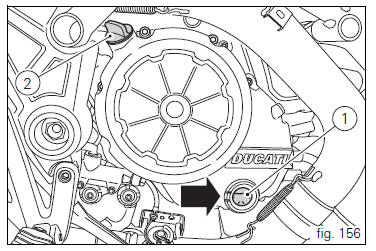

Check the engine oil level through the sight glass (1) on the clutch cover. When checking oil level, the motorcycle should be perfectly upright and the engine cold. The oil level should be between the two marks next to the sight glass. If level is low, top up with shell advance ultra 4 engine oil. Remove the filler plug (2) and top up to correct level. Replace the filler cap.

Important

Important

Engine oil and oil filters must be changed by a ducati dealer or authorised service centre at the intervals specified in the scheduled maintenance table reported in the warranty booklet.

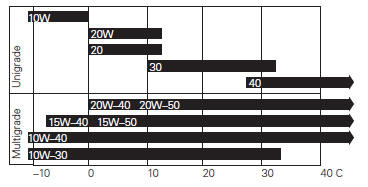

Viscosity

Sae 15w-50

The other viscosity values shown in the table can be used if the local average temperature falls within the limits specified for that oil viscosity.

Tubeless tyres

Tubeless tyres

Front tyre pressure:

2.50 Bar (rider only) - 2.6 Bar (with passenger and/or bags)

rear tyre pressure:

2.50 Bar (rider only) - 2.6 Bar (with passenger and/or bags)

as tyre pressures are affected by ...

Cleaning and replacing the spark plugs

Cleaning and replacing the spark plugs

Spark plugs are essential to smooth engine running and

should be checked at regular intervals.

The condition of the spark plugs provides a good indication of

how well the engine is running.

Ha ...

Other materials:

Reassembling the clutch

Position the spacer (13).

Fit the flat ring (11) and the belleville washer (10) on the clutch center

(12), so that the convex side faces the clutch

drum.

Locate the belleville washer (8).

Apply the prescribed grease to the thread of the gearbox primary shaft and

the mating surfac ...

Units of measurement modification function

This function allows you to change the units of measurement

of the displayed values.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?" " select the "set units" function

and pre ...

Refitting the number plate holder

Place the number plate light (5), as indicated, on the number plate holder

plate (8) and tighten the screws (7) to a torque

of 2 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Thread the number plate light wiring (c) into the opening in the number plate

holder plate as shown.

Fit ...