Ducati Diavel Service Manual: Checking the camshafts and supports

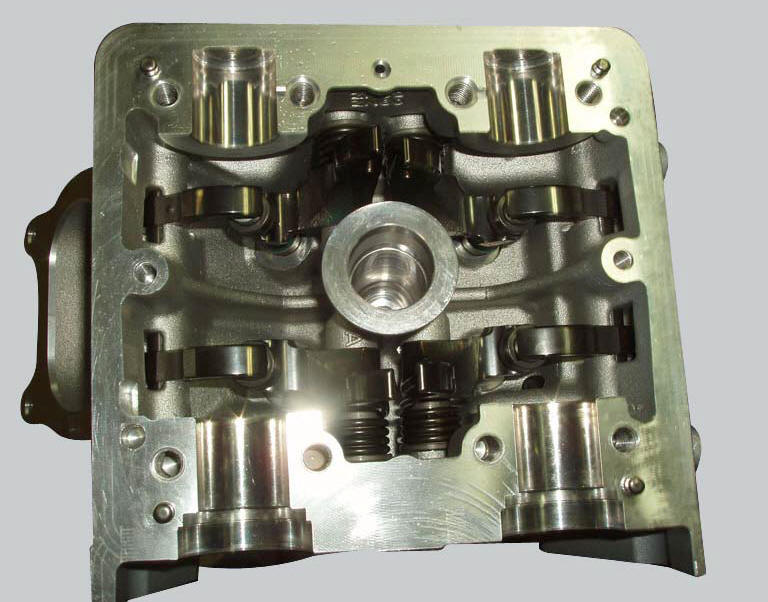

Check the cam contact surfaces for scratches, grooves, steps and waving.

Worn cams are frequently the cause of poor timing, which leads to loss of engine power.

Place the camshaft between two centres and check the run-out on the areas indicated using two dial gauges.

Service limit: 0.1 Mm.

Visually inspect the camshaft tracks for scoring and abnormal wear. If any of the above defects are found, the camshaft should be renewed.

If you find scoring or excessive wear, check the operation of the engine lubrication circuit.

Removal of the camshafts

Removal of the camshafts

Unscrew and remove the screws (7) and the o-rings (8) from the cylinder head

covers.

Remove the cylinder head cover (6).

Remove the gaskets (4) and (9).

Repeat the same procedure fo ...

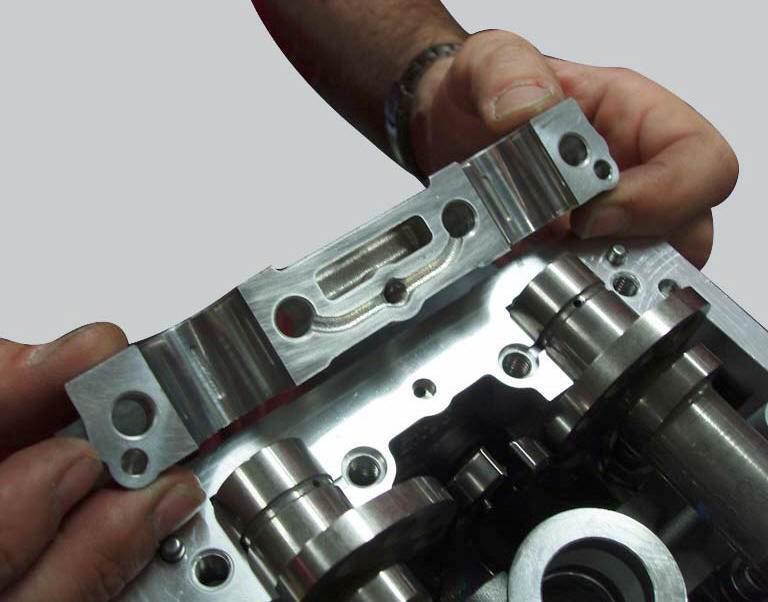

Refitting the camshafts

Refitting the camshafts

If the stud bolts (2) were removed, apply the recommended threadlocker to the

short end of the stud bolts (2), i.E. The

end that is to be screwed into the cylinder head. Tighten the stud bolts (2) ...

Other materials:

Tool kit and accessories

The tool kit (2) is located under the seat (1) while the owner’s

manual is housed in the compartment under the seat.

The tool kit includes:

Fuse pliers;

Two helmet anti-theft cables;

Screwdriver;

Screwdriver handle;

14/16 Mm box wrench;

6 Mm rod;

3 Mm allen wrench;

4 Mm allen ...

Anti-pollution system and auto-adaptive strategy

Efficacy of the catalytic converter and oxygen sensors

To comply with current emissions legislation, the diavel is equipped with a

trivalent catalytic converter, which oxidises co

(carbon monoxide) and hc (unburnt hydrocarbons) and reduces nox (nitrogen

oxides).

The image shows the exhaus ...

Fault indication

The dds (diagnosis ducati system) indicates all active errors and all

inactive but stored errors gathered by the bbs. A

simplified summary of the active errors is also shown in the master dashboard

service display when the dashboard is

switched on. Simultaneously, the eobd warning light is als ...