Ducati Diavel Service Manual: Checking valve clearances

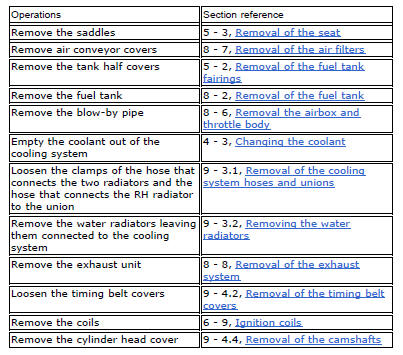

To check the valves clearance, it is necessary to have access to the cylinder head covers and then remove the components listed below.

Unscrew the two fixing screws (1) of the cover (2) according to the crankshaft.

Fit the tool handgrip 88713.0123 In the holes of the generator cover to be able to turn the crankshaft so that the valve on which the control is carried out is in rest position.

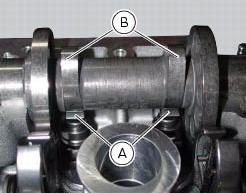

With the valve in the rest position, slide a feeler gauge between rocker arm (a) and the lowest side of the cam (b) to measure the clearance.

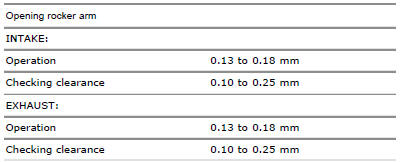

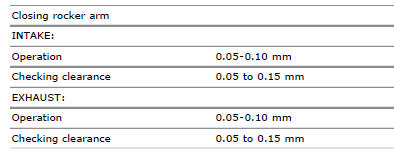

The clearances must be within the specified limits:

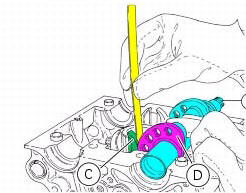

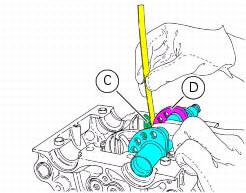

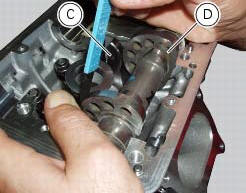

With the valve in the rest position, slide a feeler gauge between closing

rocker arm (c) and the highest side of the cam

(d) to measure the clearance.

If detected values exceed the specified limits, replace opening and/or closing shims, as described in paragraph "removing the valves" (sect. 9 - 4.5), With an adequate height to obtain the specified clearance.

Note

Opening rocker arm shims measuring from 1.8 To 3.45 Mm and closing rocker arm shims measuring from 2.2 To 4.5 Are available as spare parts. The size is punched on the shim.

Remove the handgrip tool 88713.0123 From the hole of the generator cover.

Make sure that the o-ring (3) is fitted on the cover (2).

Refit the external cap (2) by tightening the two retaining screws (1) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Change timing belts

To replace the timing system belts follow the procedures described in paragraph "removal of the movable tensioner/timing belt" and "refitting the timing belts" (sect. 9 - 4.2).

Changing the engine oil and filter cartridge

Changing the engine oil and filter cartridge

Note

This operation has to be carried out with hot engine (but turned off)

because the oil in these conditions is more fluid and

its evacuation is faster and complete.

Remove the drain plug (3) w ...

Spark plugs replacement

Spark plugs replacement

Check the colour of the ceramic insulation around the central electrode:

an even, light brown colour indicates the engine is in good condition and

running at the right temperature.

Inspect the c ...

Other materials:

Refitting the fuel tank fairings

Make sure that the following components are fitted on the tank fairing (22):

Spacers (18);

Seals (20).

Fit the clips (19) to the central cover (22) at the positions shown,

inserting the tabs (h) into the slots (l).

Apply threadlocker to the screws (14).

Place the tank fairing (22) ...

Fuel tank

fuel tank

Rubber pad

Spacer

Screw

Hose

Tray

Y-fitting

Hose

Hose

Filler cap

Screw

Complete hose guide

Screw

Hose clip

Hose

Screw

Screw

Sealing washer

Screw

Flange

Sealing washer

Spare parts catalogue

Diavel abs fuel tank

Diavel abs fuel system

Diav ...

Low battery level

The activation of this (amber yellow) "warning" indicates that the status of

the battery vehicle is low.

It is activated when the battery voltage is ¼ 11.0 Volt.

Note

In this case, ducati recommends charging the battery as soon as possible

with the specific device, as it is possible th ...