Ducati Diavel Service Manual: Checking valve lift

Set the engine to the configuration described for the "checking and adjusting the valve clearances", previously indicated.

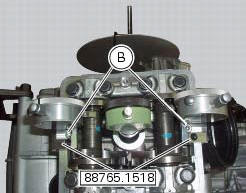

Position the tool 88765.1518 On the cylinder head: the part marked "a" should be on the intake side and the part marked "s" should be on the exhaust side.

Seat the plate (a) and tighten the screws (b).

Set the opening valve clearance to zero when the camshaft is in its rest position by fitting a feeler gauge between the upper rocker arm and the opening shim.

Lock the dial gauge into the seat of the stand marked "a" and position the fork probe against the face of the closing shim.

Set the dial gauge to zero when the valve is fully closed.

Rotate the intake camshaft so as to allow the intake valves to lift fully.

Check on the dial gauge that the measured value corresponds to the prescribed one (sect. 3 -1.1, Timing system/valves).

Repeat the same operation for the exhaust valves, using the dial gauge in the support seat 88765.1518 With the marking "s".

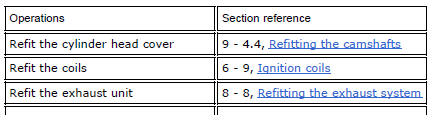

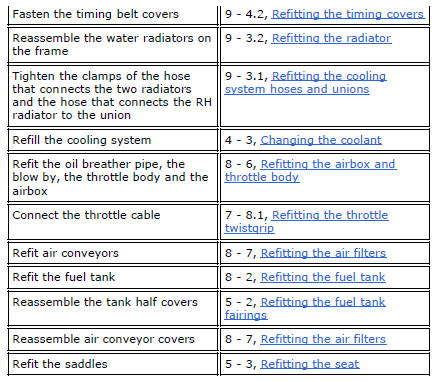

Refit the components by carrying out the same operations indicated in chapter "checking and adjusting the valve clearances", previously described.

Refit the components removed in the procedure.

Checking and adjusting the valve clearances

Checking and adjusting the valve clearances

Note

For clarity, the figures show the engine removed from the frame.

Move the piston of the cylinder being checked to tdc of the power stroke: in

this condition, all the valves are closed and ...

Checking the engine timing

Checking the engine timing

Set the engine to the configuration described for the "checking and adjusting

the valve clearances", previously indicated.

Install tool 88765.1188 (G) in the spark plug bore to determine the ...

Other materials:

Removal of the front forks

Before removing the front forks, it is first necessary to remove the

following parts:

Loosen the clamp screws (1) holding the fork legs to the steering head (3).

Loosen the clamp screws (2) and (26) securing the fork legs to the bottom yoke

(4).

Withdraw the fork legs (5) and (6) downwar ...

Refitting the crankshaft/connecting rod assembly

Install the connecting rod assembly (6) and (2) in the crankcase, carry out

the shimming and crankcase half reassembly

procedure as described in sect. 9 - 9.2, Reassembly of the crankcase halves.

Important

Make sure that the connecting rods (2) are correctly positioned in the

cylinders. Incor ...

Removal of the crankshaft/connecting rods assembly

After separating the crankcase halves, withdraw the crankshaft (6) complete

with connecting rods (2).

...