Ducati Diavel Service Manual: Communication antenna

Introduction

The communication antenna enables the hands free system to detect and communicate with the active or passive key.

The active key is detectable within a range of 1.5 Metres, whereas the passive key (or active key with flat battery) can only be detected if placed in contact with the lower part of the clear plexiglas windscreen covering the antenna.

An antenna fault will compromise correct key detection.

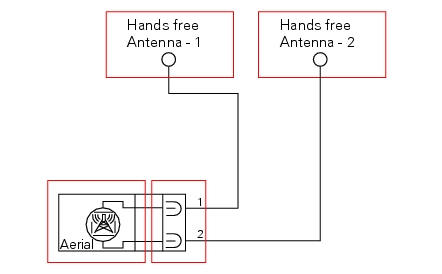

Wiring diagram

The communication antenna is connected to the hands free system by two cables and a dedicated connection.

- Blue/black (b/bk)

- Red/yellow (r/y)

Error codes

"Hands free diagnosis" error: "antenna": antenna not detected (open circuit)

or antenna short circuited. The following icon

appears on the tank dashboard:

- Check that the antenna is in working condition by measuring its electrical resistance.

- Check the integrity of the electrical circuit and the relative connections.

Note

Checking the integrity of the electrical circuit entails the following actions:

- Check the wires for continuity and check the state and integrity of the connections.

- Check that the wires are not short circuited to one another, to vdc or to ground.

Short circuit to vdc: with the dashboard on, use a voltmeter to measure the voltage between the wire being tested and ground.

Short circuit to ground: with the battery cables disconnected, use an ohmmeter to check for continuity between the wire being tested and ground.

Open circuit: with the battery cables disconnected, use an ohmmeter to check that there is no continuity between the two ends of the wire being tested.

- If none of the tests described above identifies the problem, replace the hands free system.

Electrical characteristics and checking component

The resistance between the two terminals of the component side connection must be approximately 2 ohm.

In the event of fault

In the event of a component fault, the hands free system can no longer detect and recognise the keys. The pin code procedure must be used to start the motorcycle.

Installation location

The image shows the location of the hands free system antenna.

Location of hands free system antenna on antenna side.

Component replacement methods

No special measures are necessary in order to replace the hands free system communication antenna.

The hands free module

The hands free module

Introduction

The hands free module incorporates the control unit communicating with the

other nodes on the motorcycle, the on/off

button, the microswitches detecting full lock steering angle (for ...

On/off switch on handlebar

On/off switch on handlebar

Introduction

The on/off switch on the handlebar is used to switch the dashboard on and

off, if a key has been detected, and start the

engine.

With the switch turned to "run off" (centre positio ...

Other materials:

Removal of the timing belt covers

Loosen the screws (4) securing the central external cover (1) and remove it

from the central side.

Undo the fixing screws (4) of the external cover (25) and remove it from the

vertical thermal unit.

Undo the fixing screws (4) of the external cover (3) and remove it from the

horizonta ...

Stored lap display function

This function displays the stored laps.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?" " select the "lap" function and

press the reset button

(12, fig. 12) To go to next pag ...

Trip 2 meter

This function shows the distance travelled since the trip meter was last

reset (in km or miles depending on the specific

application).

Press and hold (1) "s" for 3 seconds while in this function to reset the trip

odometer.

When the reading exceeds 9999.9, Distance travelled is reset and t ...