Ducati Diavel Service Manual: Disassembly of structural components and the frame

Before carrying out dimensional checks on the frame, you must remove all the superstructures fitted, referring to the removal procedures outlined in the sections of this manual.

The rear subframes (2) and (3) are structural components of the frame (1).

Both serve to support motorcycle superstructures and must therefore be in perfect condition.

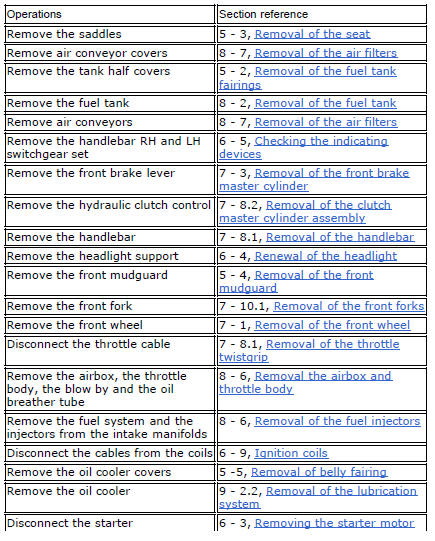

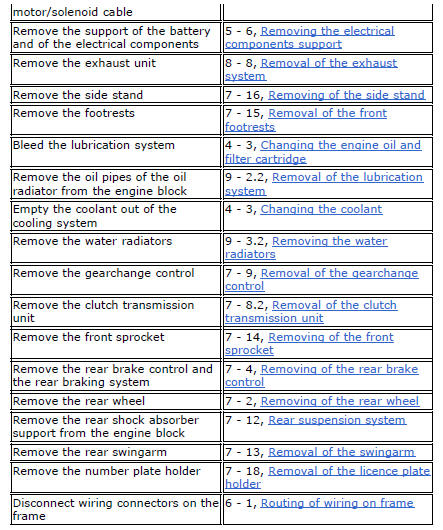

The following flow chart illustrates the logical sequence in which the parts are to be removed from the motorcycle and a reference to the section where the removal procedure is described.

Refitting is the reverse of removal.

Frame inspection

Frame inspection

Frame

Rh subframe

Lh subframe

Grub screw

Nut

Special screw

Rubber pad

Nut

Special screw

Screw

Left-hand bracket

Hose clip

Hose clip

Right-hand bracket

Special screw

...

Removal of the tool tray

Removal of the tool tray

To remove the tool tray unit from the lateral footrests, loosen the screws

(40) and remove the splashguard (20).

Undo the screws (15) and remove the cover (16).

Move the wiring branch ...

Other materials:

Exhaust by-pass valve not working correctly

Fault codes

Dds: exvl diagnosis -> position error, potentiometer, short circuit to ground

or open circuit (s.C. Gnd or c.O.),

Potentiometer short circuited to vdc (potentiometer s.C vdc).

Dashboard: the error "exvl" (exhaust bypass valve) is shown on the service

display. The eobd warning ...

Vehicle speed indicator

This function displays vehicle speed (km/h or mph depending on the set

measurement system).

The dashboard receives information about the actual speed and displays the

number increased by 5%.

Maximum speed displayed is 299 km/h (186 mph).

Over 299 km/h (186 mph) the display will show a s ...

Recovery procedure with no key

When the dashboard is on and the key has been recognised, the hands free

attempts to detect the key every 60 seconds.

If the engine is off and the on/off switch on the handlebar is turned to "run

off", if no key is detected within 10 seconds,

the dashboard switches off automatically.

If t ...