Ducati Diavel Service Manual: Disassembly of the gearbox shafts

Place the shaft in a vice in such a way as to facilitate the disassembly operations.

Important

Take care not to invert the positions of the shims on reassembly: this would potentially lead to jamming when using the gear selector control, making it necessary to reopen the engine crankcase.

Disassembly of the gearbox secondary shaft

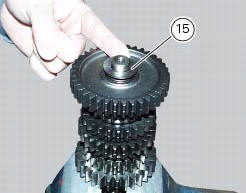

Remove the chain-side shim washer (26) and clutch-side shim washer (15) from the secondary shaft.

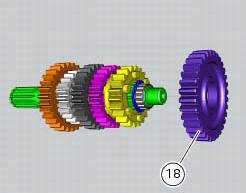

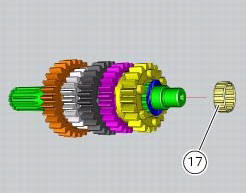

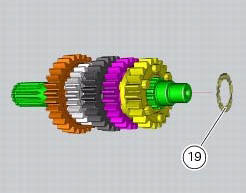

Withdraw the first speed driven gear (18) with the roller cage (17) and the shim (19).

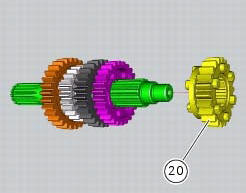

Remove the fifth speed driven gear (20).

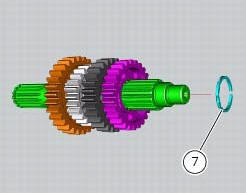

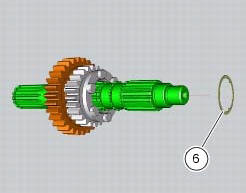

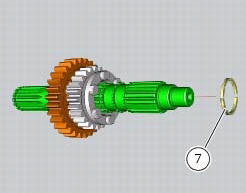

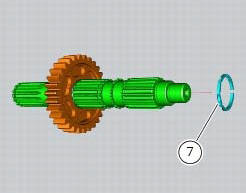

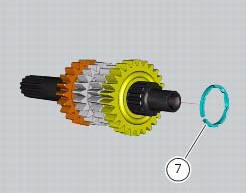

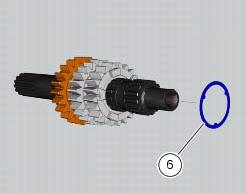

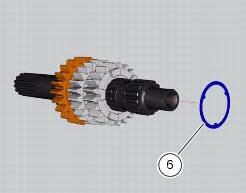

Use two flat blade screwdrivers to remove the circlip (7) taking care not to damage the shaft surface.

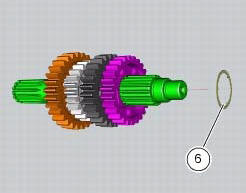

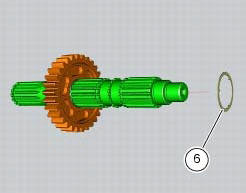

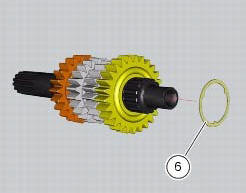

Remove the circlip (7) and the splined washer (6).

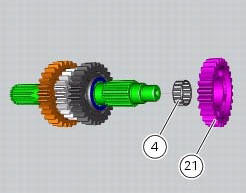

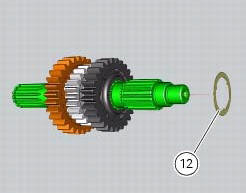

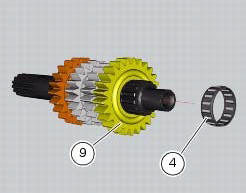

Withdraw the fourth speed driven gear (21) with the roller cage (4) and splined washer (12).

Remove the

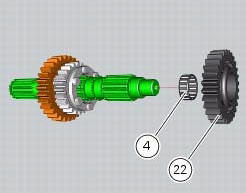

Remove the third speed driven gear (22) with the roller cage (4) and the splined washer (6).

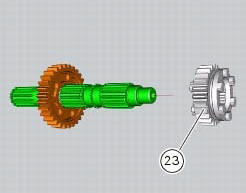

Remove the circlip (7) and remove the sixth speed driven gear (23).

Remove

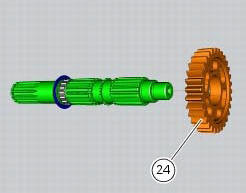

Remove the circlip (7) and withdraw the splined washer (6) and the second speed driven gear (24).

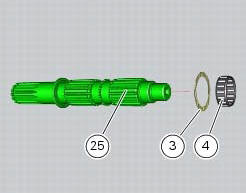

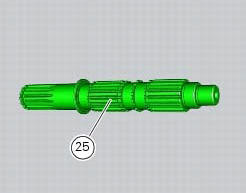

Withdraw the roller cage (4) and the shim (3). All the components have thus been removed from gearbox secondary shaft (25).

Disassembly of the gearbox primary shaft

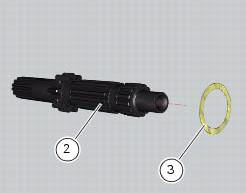

Remove the chain-side shim washer (11) and the clutch-side shim washer (1) from the primary shaft.

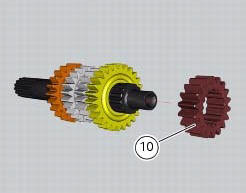

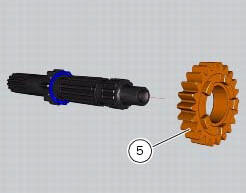

Remove the second speed driving gear (10). Use two screwdrivers to prise out the circlip (7) and the splined washer (6).

Important

Take care to avoid damaging the surface of the shaft while removing circlip (7).

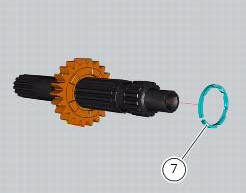

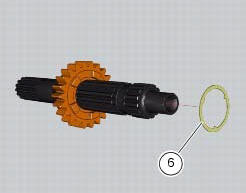

Remove the sixth speed driving gear (9) with its roller cage (4). Remove the splined washer (6) and the circlip (7).

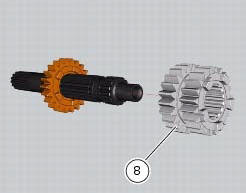

Withdraw the third and fourth speed driving gear (8).

Remove the circlip (7) and the splined washer (6).

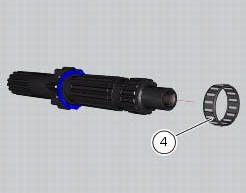

Remove the fifth speed driving gear (5) with the roller cage (4).

Slide the shim (3) off the primary shaft (2).

Removal of the gearbox assembly

Removal of the gearbox assembly

Withdraw the selector fork shafts (30).

Move the forks (28) and (29) to disengage them from the slots in the selector

drum (14).

Withdraw the selector drum (16) taking care not to lose s ...

Overhaul of the gearbox

Overhaul of the gearbox

Check the condition of the front coupling dogs of the gears. They must be in

perfect condition and with no sign of wear on

the edges of the teeth.

The idler gears must rotate freely on their sha ...

Other materials:

Default function (resetting ducati default parameters)

This function resets the parameters set by ducati for each

riding style.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"

" or (2, fig. 14) ?" " select the "riding mode"

function and press the

r ...

Transmission

Wet clutch controlled by the lever on left-hand side of the

handlebar.

Transmission from engine to gearbox primary shaft via spur

gears.

Front chain sprocket/clutch gearwheel ratio:

33/61

6-speed gearbox with constant mesh gears, gear change

pedal on left side of motorcycle.

Gearbox ou ...

Trip 2 meter

This function shows the distance travelled since the trip

meter was last reset (in km or miles depending on the

specific application).

Holding the button (1, fig. 14) ?

pressed for 3 seconds

when this function is displayed resets the trip meter.

When the reading exceeds 9999.9, Distance t ...