Ducati Diavel Service Manual: Disassembly of the gearchange mechanism

Refer to the exploded view at the beginning of this section for indications on disassembly and renewal of gearchange components.

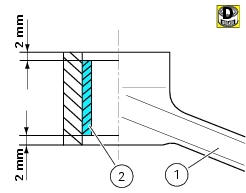

If the bushing (2) inside the pedal (1) needs replacing, grease the external surface and drive the new bushing into place using a press. The bushing must be seated 2 mm below the outer face of the pedal.

Warning

After working on the gearchange control, check the position of the gearchange pedal.

To adjust the gearchange pedal position, follow the instructions indicated in sec. 4 - 3, Adjusting the position of the gear change and rear brake pedals.

Removal of the gearchange control

Removal of the gearchange control

Loosen and remove the pivot screw (4) securing the gearchange pedal (1) and

recover the washer (9) and the o-ring Seals (5).

Loosen and remove the screw (7) securing the gearchange lever (8 ...

Refitting the gearchange mechanism

Refitting the gearchange mechanism

Make sure that the gearchange linkage assembly (6) is installed with the ball

joint with a left-hand thread (a) facing the

lever (8).

Apply the recommended grease to the non-threaded surface of ...

Other materials:

Refitting the handlebar

Position the handlebar (4) so that the external lower corner of the marks (a)

on the handlebar matches the upper internal

corner of the lower u-bolts (b) as shown.

Apply the recommended grease to the threads and undersides of the heads of

the screws (3).

Important

Position the upper u-bo ...

Tft - parameter setting/display

Warning

Any adjustments to the instrument panel must only be

carried out when the motorcycle is stationary. Never operate

the instrument panel controls while riding the motorcycle.

At the end of the check, the instrument panel always

displays as the "main" indication the odometer (to ...

Menu 2 on/off function

This function turns off and back on the menu 2.

If menu 2 is disabled, the functions for average fuel

consumption (cons.Avg), instantaneous fuel consumption

(cons.), Average speed (speed avg), trip time (trip time)

and air temperature (air) will no longer be displayed in the

"main screen ...