Ducati Diavel Service Manual: Disassembly of the rear brake control

The brake master cylinder is supplied only as a complete unit; internal components cannot be replaced.

To disassemble the master cylinder's outer parts, follow the indications given in the exploded view at the beginning of this section.

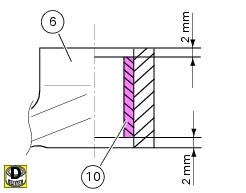

If the bush (10) inside the brake pedal (6) needs to be replaced, grease the external surface and fit the new bush using a press to insert it. The bush must be placed at 2 mm from the pedal external face.

To disassemble the various parts of the system, refer to the exploded view at the beginning of this chapter.

Warning

After performing an operation on the rear brake control, check the brake pedal position following the instructions detailed in sect. 4 - 3, Adjusting the position of the gear change and rear brake pedals.

Removing of the rear brake control

Removing of the rear brake control

Warning

The brake master cylinder manufacturer advises against servicing the

brake master cylinder due to the safety critical

nature of this component.

Incorrect overhaul can endanger the rider ...

Refitting the rear brake control

Refitting the rear brake control

If the pushrod (18), clip (30) and fork (31) assembly has been dismantled,

reassemble it by screwing the nut (29) onto

the rod (18) and then screw the rod into the fork (31) to obtain the measureme ...

Other materials:

Removal of the steering head components

Note

All parts fitted to the top and bottom yokes, including the wiring and

control cables, can remain on the motorcycle

provided they do not hinder the following operations.

Loosen the screws (19) securing the supports (21) and (23) of splashguard

(22) to the air conveyors (t).

...

Removal of the clutch transmission unit

Warning

The manufacturer of the clutch transmission unit (15) advises

against servicing of its internal parts due to the safetycritical

nature of this component.

Incorrect overhaul of these critical safety components can endanger rider and

passenger safety.

The only components that shoul ...

Limited liability

The liability of ducati under this emission control systems

warranty is limited solely to the remedying of defects in

material or workmanship by an authorized ducati motorcycle

dealer at its place of business during customary business

hours. This warranty does not cover inconvenience or l ...