Ducati Diavel Owners Manual: Electric system

Basic electric items are: headlight: low beam bulb type: 1xh7 blue vision (12v-55w); high beam bulb type: 1xh1 (12v-55w); parking light: led (12v-2.4W).

Electrical controls on handlebars.

Turn indicators: front: led (13.5V-2.9W).

Horn.

Brake light switches.

Sealed battery, 12v-10 a.

Generator 12v-430w.

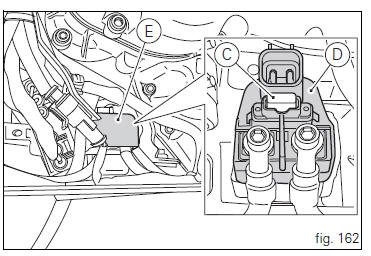

Master fuse, protected by a 30a fuse located on the solenoid starter, behind the battery (c, fig. 162).

Starter motor: 12v-0.7 Kw.

Tail light, brake light and rear turn indicators: parking: (13.5V-0.6W); stop: led (13.5V-2.8W); rear turn indicators: led (13.5V-2.06W).

Number plate light: led (13.5V-0.67W).

Note

Note

See "replacing the high and low beam bulbs" on page 158 for relevant instructions.

Fuses

There are twelve fuses that protect the electric components located inside the front and rear fuse boxes, and one on the electric solenoid starter. There is a spare fuse in every box.

Refer to the table below to identify the circuits protected by the various fuses and their ratings.

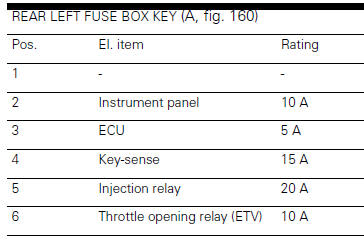

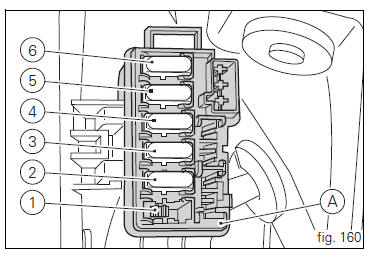

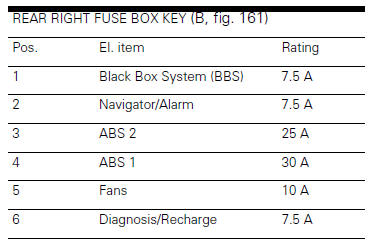

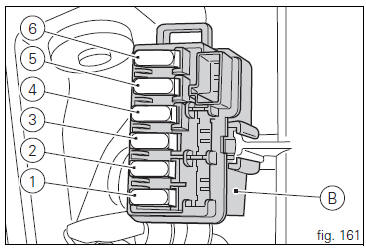

The rear left fuse box (a, fig. 160) And the rear right one (b, fig. 161) Are located under the seat, inside the underseat compartment.

To access the fuses, remove the seat (see "removal of the seat" on page 119).

To expose the fuses, lift the box protective cover. Mounting position and ampere capacity are marked on box cover.

Note

Note

Remove the left cowling to reach the main fuse (see "charging the battery" on page 148).

The main fuse (c, fig. 162) Is positioned next to the battery, on the solenoid starter (d). Remove the fuse cap (e) to reach it.

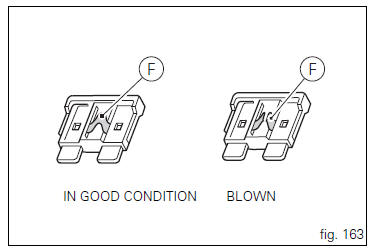

A blown fuse is identified by the interrupted centre link (f, fig. 163).

Important

Important

To prevent short circuits, replace the fuse after the key-off.

Warning

Warning

Never use a fuse with a rating other than specified.

Failure to observe this rule may damage the electric system or even cause fire.

Injection /electric system diagram key

- Right-hand handlebar switch

- Immobilizer

- Hands free relay

- Hands free

- Front fuse box

- Right fan

- Left fan

- Fan relay

- Fuel pump relay

- Ride-by-wire relay (etv)

- Injection control unit (ems)

- Rear fuse box

- Data acquisition/diagnosis

- Starter motor

- Fused solenoid

- Battery

- Wiring ground

- Regulator

- Generator

- Fuel pump

- Fuel level

- Rear right turn indicator

- Rear light

- Rear left turn indicator

- Vehicle control unit (bbs)

- Antitheft alarm

- Exhaust valve starter motor

- Gear sensor

- Rear speed sensor

- Abs control unit

- Throttle twistgrip position sensor (aps)

- Starter motor - position sensor / ride-by-wire (tps/etv)

- Timing/rpm sensor

- Vertical map sensor

- Horizontal map sensor

- Engine temperature

- Air temperature sensor

- Vertical lambda sensor

- Horizontal lambda sensor

- Oil pressure switch

- Rear stop

- Side stand switch

- Clutch switch

- Front stop

- Main vertical injector

- Main horizontal injector

- Horizontal coil

- Vertical coil

- Left-hand handlebar switch

- Horn

- Front speed sensor

- Front left turn indicator

- Instrument panel on handlebar

- Instrument panel on tank

- Front right turn indicator

- Navigator

- High / low beam

- Parking light

Wire colour coding

B blue

W white

V violet

Bk black

Y yellow

R red

Lb light blue

Gr grey

G green

Bn brown

O orange

P pink

Note

Note

The electric system wiring diagram is at the end of this manual.

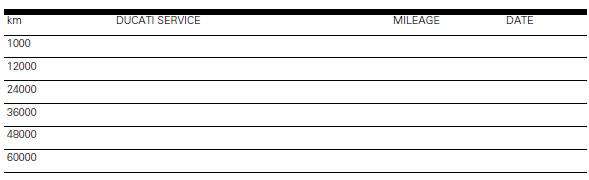

Scheduled maintenance reminder

Colour schemes

Colour schemes

Ducati red enamel code 54d234015 (akzo);

red frame and black rims.

Diamond black code 57e22714 (akzo);

enamel code 54m22705 (akzo);

clear lacquer part no. 228.880 (Ppg);

racing black frame blac ...

Other materials:

Refitting the engine

Refitting is the reverse of removal.

Important

Apply recommended grease and tighten the special screws (6) to a torque of

60 nm +/- 5% (sect. 3 - 3, Frame torque

settings).

Tighten the nuts (3) to a torque of 48 nm +/- 5% (sect. 3 - 3, Frame torque

settings).

Warning

For the assembly seque ...

Keys (fig. 62)

The owner receives a set of keys comprising:

1 Active key (1, fig. 62)

1 Passive key (2, fig. 62)

It contains the code used by the "hands free" system for the

key-on, in different modes.

The active key (1, fig. 63) Is the one that is normally used:

press button (a, fig. 63) To ...

First warning - oil service 1000 km

The first warning is activated at 1000 km (600 miles) of odometer reading.

The (red) warning is activated as a large icon for 10 seconds upon every key-on

(1) then as a small warning that

remains displayed (2) until it is reset.

...