Ducati Diavel Service Manual: Electrical power for lighting and signalling devices

The front and rear running lights consist of led units with light conduits. As a result, the light source is not visible as the light is diffused through the surface of the light conduit.

These two images illustrate the front and rear running lights with light conduits.

The figure shows the locations of the low beam bulbs (lo), high beam bulbs (hi) and the parking light led light unit (1).

Rear view of the headlight showing the high and low beam light connections and the connection for the led power module at the centre, with the connector cable.

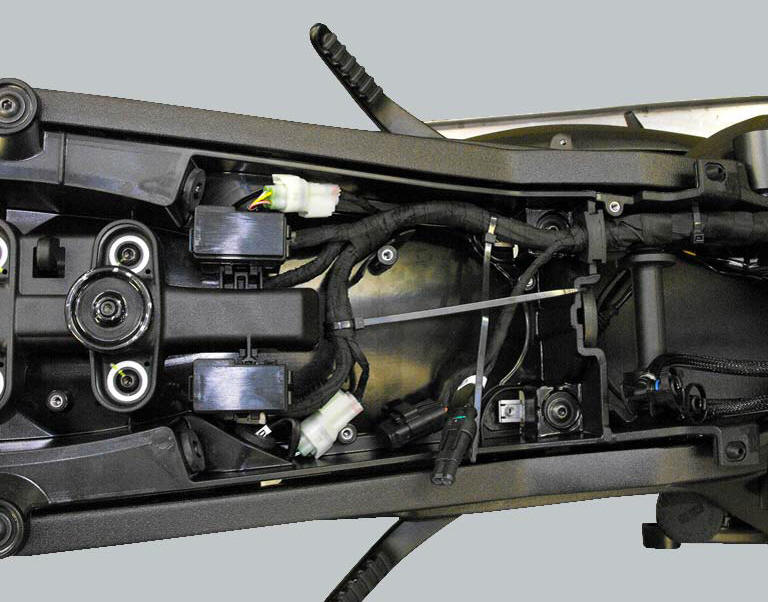

To access the tail light - turn indicators unit, remove the seat as described in sect. 5 - 3, "Removal of the seat" and the tool tray cover as described in sect. 7-17, "Removal of the tool tray".

The bbs and the dash board unit provide electric power to the lighting and signal devices, which therefore have no conventional power supply passing via a fuse and no electric switchgear set on the handlebar. Commands for the lights and signals are in fact sent to the control units, which then activate the relative lighting devices. The following table indicates the types of devices used, the type of power supply and whether or not the devices are testable.

| Device type | Power type | Function |

| Front led turn indicators, commanded directly from dash board | Pwm without specific fuse | Not testable |

| Rear turn indicators with incandescent bulbs, commanded directly from bbs | 12V without specific fuse | Bulb function may be tested |

| Number plate light with incandescent bulb commanded directly from dash board | Pwm without specific fuse | bulb function may be tested |

| Low beam lights with incandescent bulbs | 12V with fuse | Bulb pwm |

| High beam lights with incandescent bulbs | 12V with fuse | Bulb function may be tested |

| Front and rear led running lights, commanded directly from bbs | 12V without specific fuse | Device function may be tested using an external 12v power source |

| Led stop light, commanded directly From bbs | 12V without specific fuse | Device function may be tested using an External 12v power source |

As soon as you start the engine the low beam turns on automatically. In key-on condition and engine off it is possible to turn on the high and low beams that will switch off after 60 seconds if the engine is not started: in key-on condition the headlights are off, in key-on and engine running the headlights turn on automatically and in key-on it is possible to turn them on with the lh switch.

Ground connection locations

Ground connection locations

The negative cable, which is normally connected to the negative pole of the

battery, is fastened to the crankcase. From here, the cable

branches off and splits up within the electrical system to ca ...

Location of elements on motorcycle

Location of elements on motorcycle

(A) injection relay; (b) etv relay (throttle valve operating engine); (c)

radiator fan relay; (d) hands free relay.

(E) ecu; (g) bbs (black box system or central electronics); (f) abs h ...

Other materials:

Refitting the filler cap

Position seal (18) in tank cap (10) as shown and reassemble following the

removal procedure in the reverse sequence.

In particular tighten the screws (17) to a torque of 3 nm +/- 10% (sect. 3 - 3,

Frame torque settings).

...

Refitting the timing belts

Rotate the pulleys on the timing belt driveshaft until the timing mark on the

outer roller is aligned with the mark on the

clutch-side crankcase cover.

In this condition, the horizontal cylinder piston will be at top dead centre.

Install in the alternator cover seat the tool code 88713.20 ...

Removal of the gear selector lever

Unscrew and remove the fixing screws (18) and (20) of the complete gear

selector lever (21) and collect the spacer (19).

Remove the gearchange mechanism complete with the shaft, spring, and stop plate.

Important

Visually inspect the gear selector claw (14) for wear, particularly aroun ...