Ducati Diavel Service Manual: Engine temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures the temperature of the coolant (engine temperature). This sensor has a resistance of ntc type (negative temperature coefficient), that reduces its own value when the temperature increases. The engine temperature sensor, allows the control unit to manage correctly the cold starting and the heating phases.

Components assembling position

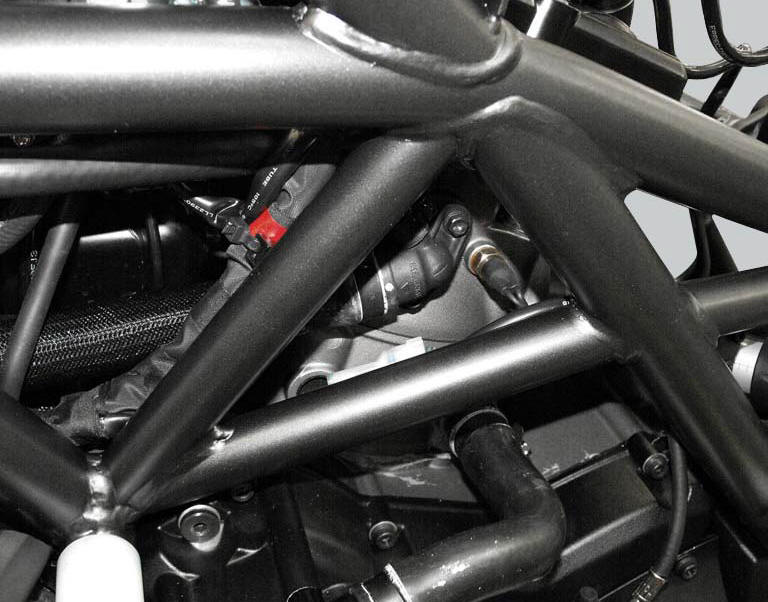

The engine temperature sensor is mounted on the left hand side of the vertical cylinder.

Location of engine temperature sensor connector.

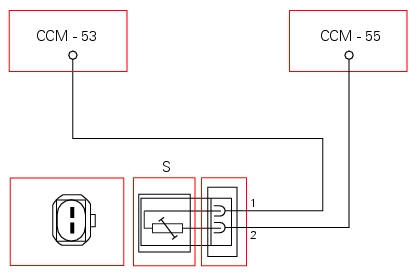

Wiring diagram

Ccm engine control connection, s engine temperature sensor. 1 Green/white - g/w, 2 black/purple - bk/v.

In the event of fault

In the event of an engine temperature sensor fault, the engine control unit implements a recovery value of 70C and activates the radiator fans.

Fault codes generated and possible correlated faults

Fault codes generated by the engine control unit and displayed by the dds (engine temperature sensor diagnosis):

- Short circuit to vdc: check integrity of electric circuit, check integrity of electrical connections

- Short circuit to ground: check integrity of electric circuit, check integrity of electrical connections

- Open circuit: check integrity of electric circuit, check integrity of electrical connections

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

The tank dashboard shows the error "engine temperature" and the eobd warning light activates.

When the dashboard receives the "engine temperature" error, flashing dashes are displayed instead of the temperature reading. If the dashboard does not receive engine temperature information from the can line, the error "engine temperature" is not shown on the display, but flashing dashes are still displayed instead of the temperature reading.

Possible correlated faults: inadequate engine power, irregular idle speed (target idle speed is 1350 rpm with engine stabilised at operating temperature), the engine does not start easily, radiator fans not activated correctly or not activated at all, causing the coolant to reach boiling point.

Check:

- Sensor resistance, which must be approximately 10 kohm at 25C and approximately 1270 ohm at 90C

The engine temperature value may be checked using the dds. Check that the value given is plausible.

If none of the aforementioned tests identify the problem and the engine temperature sensor is in proper working order, replace the engine control unit.

component replacement methods

No special measures are necessary in order to replace the engine temperature sensor. After replacement of the engine temperature sensor, reset the self-adaptive parameters relative to carburation with the dds.

Air temperature sensor

Air temperature sensor

Introduction

The engine control system on the diavel uses a sensor that measures air

temperature. This sensor has a resistance of

ntc type (negative temperature coefficient), that reduces its own ...

Absolute pressure sensors

Absolute pressure sensors

Introduction

The engine control system of the diavel is equipped with two absolute

pressure sensors, with one connected to the intake

duct of each cylinder (map 1 cylinder 1 - horizontal - map 2 c ...

Other materials:

Removal of the intake manifold and coolant union

Loosen the clips (f) and remove the hoses (t).

Remove the manifolds (25) undoing the screws (21).

Loosen the clamp (a) and remove the hose (b). Remove the union (12) and

recover the seal (24).

...

Removing the front footrest brackets

Note

The assembly of the front footrests is described only for the right one

(2) but it is the same also for the left one.

Place the spring (4) bringing the end (a) onto the footrest (2).

Place the footrest (2) in the correct position, by inserting the end (c) of the

spring (4) in the hole ...

Rear-view mirrors

Rear-view mirror

Screw

U-bolt

Spring washer

Spare parts catalogue

Diavel abs handlebar and controls

Diavel carbon

abs

handlebar and controls

Important

Bold reference numbers in this section identify parts not shown in the

figures alongside the text, but which can be found in

...