Ducati Diavel Service Manual: Filling the clutch circuit

Warning

Clutch fluid will damage painted surfaces if spilled on them. It is also very harmful if it comes into contact with the skin or with the eyes; in the case of accidental contact, wash the affected area thoroughly with plenty of running water.

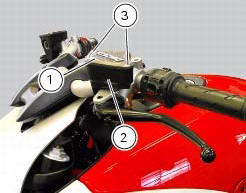

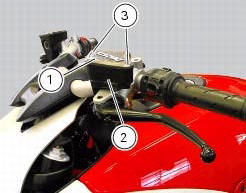

Remove cover (1) and membrane from the clutch fluid reservoir (2) by loosening the screws (3).

Fill the tank with specified oil (sect. 3 - 2, Fuel, lubricants and other fluids) taken from an intact container.

Important

During the following operation, the fluid level must remain topped up at all times. The end of the transparent plastic tubing must remain immersed in the discharged fluid at all times.

Operate the clutch lever and keep it pulled to fill the circuit and expel any air.

Connect the bleed tool to the bleed valve (4).

Note

Follow the manufacturer's instructions when using a commercial clutch bleeding tool.

Loosen the bleed valve (4) and pump with the bleeder. Make sure that the reservoir level does not fall below the min mark.

Repeat the bleeding operation until the fluid flowing from the tube is completely free of air bubbles.

If you do not have a bleeding tool available, connect a length of transparent plastic tubing to the bleed valve (4) as outlined in the draining procedure.

Open the bleed valve by 1/4 turn and operate the clutch lever several times until the fluid flows out of the bleed valve (4).

Pull the lever fully in and then loosen the bleed valve by at least a 1/4 turn.

Wait for a few seconds; then release the lever gradually while simultaneously closing the bleed valve (4).

Important

Do not release the clutch lever until the bleed valve has been fully tightened.

Repeat the bleeding operation until the fluid emerging from the plastic tube is free of air bubbles.

Close to a torque of 4 nm +/- 10% (sect. 3 - 3, Frame torque settings) the bleed valve (4) and install the protection cover.

Top up the fluid level to approximately 3 mm above the min mark of the tank.

Reassemble cover (1) and membrane from the clutch fluid reservoir (2) by tightening the screws (3).

Draining the clutch hydraulic circuit

Draining the clutch hydraulic circuit

Warning

Clutch fluid will damage painted surfaces if spilled on them. It is

also very harmful if it comes into contact with the skin or

with the eyes; in the case of accidental contact, wash the a ...

Adjusting the steering head bearings

Adjusting the steering head bearings

Excessive handlebar play or shaking forks in the steering head indicate that

the play in the steering head bearings

requires adjustment. Proceed as follows:

loosen the clamp screw (1) that holds t ...

Other materials:

Refitting the swingarm

Apply the recommended threadlocker to the screws (7).

Install the lower chain guard (15) on the swingarm (8), fastening it with the

screws (7): tighten the screws (7) to a torque

of 4 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Locate the swingarm (8) on the frame.

Lubricate with ...

Removal of the clutch

Note

For clarity, the figures show the engine removed from the frame.

Undo the fixing screws (1) and remove the ring (2) and the springs (3) from

the pressure plate (4).

Slide the pressure plate (4) paying attention to the circlips (6).

Remove the clutch control pin (14) and the ...

Setting menu

This menu is used to enable/disable and set some motorcycle functions.

To access the "setting menu" press and hold button (2) "t" for 3 seconds.

Note

When within this menu no other function can be displayed.

Important

For safety reasons, the setting menu can only be accessed when motorcycle

...