Ducati Diavel Service Manual: Fuel pressure test

Note

The on-screen icons used during this procedure are explained in a table at the end of this section.

Undo the screws (2) and remove the flange cover (1).

Remove one of the two pipes of the fuel system (3).

Use the fuel pressure pipe (4) part no. 590.1.189.1A by connecting one end (d) to the coupling of the delivery pipe to the tank and the other end (e) to the fuel system pipe (3): in this way you create a pressure pick-up socket (f).

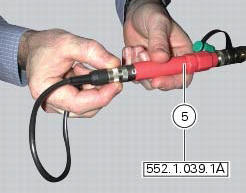

Connect the pressure sensor (5) part no. 552.1.039.1A to the outlet (f) of hose (4), in order to convert the pressure reading into an electric signal.

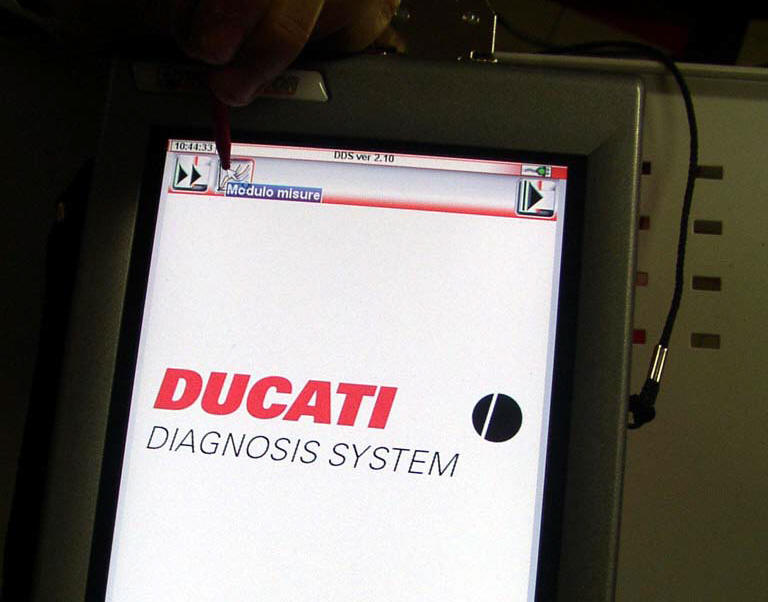

Turn on the dds diagnosis instrument (6) referring to the paragraph "tester power supply".

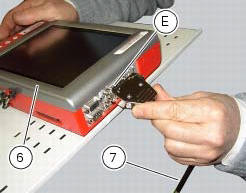

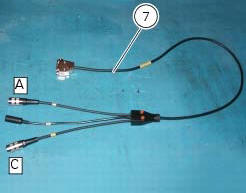

Connect the power and diagnosis cable (measurement module) (7) part no. 97900.0222 To the measurement module connector (e) of the dds (1).

Connect the pressure sensor (6) part no. 552.1.039.1A to outlet (a) or (c) of the cable (7).

On the dds diagnosis instrument (6), select the "measurement module" function by pressing the corresponding icon; then press the "pressure test" icon (f) followed by the "start" icon (g).

The socket to which the cable (measurement module) (7) is to be connected is indicated on the screen with a capital letter: a, b or c.

The values may be displayed in three different ways: in one numeric form and in two graphic forms; to select the desired display type, press the "value display" icon (h).

The measured value is indicated alongside the letter (a) or (c) identifying the cable used for the measurement: i.E. If you used socket (a) of the cable (7), the value measured will be displayed next to the letter (a) on the screen.

The maximum pressure must be equal 3 bar (nominal).

Once the test is over, remove all the components of the test instrument and refit the fuel system pipe (3).

Refit the flange cover (1) by tightening the screws (2) to a torque of 4 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Cylinder compression test

Cylinder compression test

Note

The on-screen icons used during this procedure are explained in a table at

the end of this section.

Engine performance is directly correlated to the pressure that can be

measured in the com ...

Guided diagnosis

Guided diagnosis

Note

The on-screen icons used during this procedure are explained in a table at

the end of this section.

The dds diagnosis instrument guides the operator step-by-step through the

various diagnos ...

Other materials:

Background setting function for the dashboard on tank - dashboard 1

This function allows setting the "background" of the dashboard on tank.

To access the function it is necessary to view the ""setting" menu", using

buttons (1) "s" or (2) "t" select the "back

light" function and press the reset button (3) to enter the following page.

Use button (1) "s" or (2 ...

Backlighting setting function for the instrument panel on Handlebar -

dashboard 2

This function allows backlighting setting of the instrument

panel on handlebar.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"

" or (2, fig. 14) ?" " select the "back light" function

and press ...

Introduction to the "hands free" system

The hands free system allows the rider to start the engine without physically

using the ignition key. The ignition key

merely has to be in the vicinity of the motorcycle, such as in the rider's

pocket, for example, in order to use the vehicle.

Compared to the standard ignition switches the h ...