Ducati Diavel Service Manual: High beam lights not working

Fault codes

The hi beam light on the (slave) dashboard flashes at 1hz frequency.

Wiring diagram

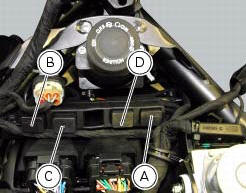

Location of elements on motorcycle

(A) injection relay; (b) etv relay (throttle valve operating engine); (c) radiator fan relay; (d) hands free relay.

Fuses located at the rear left of the vehicle.

(1) 10A dashboard; (2) 5a engine control unit; (3) 15a key-sense; (4) 20a injection relay; (5) 10a throttle opening relay (etv).

Fuses located at the rear right of the vehicle.

(1) 7.5A black box system (bbs); (2) 7.5A navigator/alarm; (3) 25a abs 2; (4) 30a abs 1; (5) 10a fans; (6) 7.5A diagnosis/recharge.

(A) low / high beam and parking light connections

Location of left hand handlebar switchgear set connection.

Pin numbering for wiring harness side dashboard connector.

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

Low beam lights not working

Low beam lights not working

Location of connections and components

(A) injection relay; (b) etv relay (throttle valve operating engine); (c)

radiator fan relay; (d) hands free relay.

Fuses located at the rear left of ...

Other materials:

Adjusting the chain tension

Make the rear wheel turn until you find the position where chain is tightest.

Set the vehicle on the side stand. Push down

the chain at the point of measurement and release. Measure the distance between

the "aperture" upper profile and pin

centre.

The read distance must be: 9 to 11 mm.

...

Refitting the rear footrests

Note

The refitting of the rear footrests is described for the right side but it

is the same for both.

If previously removed, refit the rubber footrest (11) on the rear rh footrest

(6), by pushing it until pad (b) engages in the

other side.

Note

The rubber footrest (11) side featuring the le ...

Refitting the rear mudguard

Place the rear mudguard (8) on the swingarm, fitting the screws (9) with

recommended threadlocker.

The screw (9) in the bottom hole of the rear mudguard (8) must be installed with

the washer (r).

Tighten the screws (9) to a torque of 5 nm +/- 10% (sect. 3 - 3, Frame torque

settings).

...