Ducati Diavel Service Manual: Injection relay

Introduction

The fuel pump, injectors and ignition coils are all powered via the injection relay. The relay also sends voltage to the engine control unit, which enables activation of the relay itself.

Component assembling position

A injection relay; b etv relay (throttle valve actuator motor), c radiator fan relay, d engine control unit.

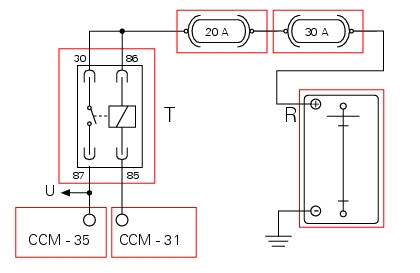

Connection wiring diagram

Ccm engine control connection, t injection relay. 85 Brown/black - bn/bk injection relay activation, 87 brown/white-bn/w ecu input voltage, u direct power to injectors, ignition coils and fuel pump, r battery power (+30), 30 and 86 brown - bn.

In the event of fault

In the event of an injection relay fault, the engine stops (if running) or will not start. The relay is not commanded by the ecu.

Fault codes generated and possible correlated faults

Fault codes generated by the engine control unit and displayed by the dds (fuel injection relay diagnosis):

- Open circuit: check integrity of fuses, electrical circuit and electrical connections.

- Short circuit to ground: check integrity of fuses, electrical circuit and electrical connections.

- Short circuit to vdc: check integrity of electric circuit and electrical connections.

Note

Check integrity of electric circuit - short-circuit to vdc = with dashboard on, using a voltmeter, a voltage is measured between the wire tested and ground.

Check integrity of electric circuit - short-circuit to ground = with the battery cables disconnected, using an ohmmeter, continuity is detected between the wire tested and ground.

Check integrity of electric circuit - open circuit = with the battery cables disconnected, using an ohmmeter, no continuity is detected between the two ends of the wire tested.

The dashboard service display shows the error "fuel injection" and the eobd warning light activates.

Possible correlated faults: the engine stops (if running) or will not start. Check:

- Integrity of fuses

- Relay function. After removing from its mounting, apply 12 v power to pin 85 and pin 86 of the relay and check that pin 87 and pin 30 close (continuity between pins)

Using the dds, activate the ignition coils, the fuel pump or the injectors. The injection relay is driven and its contacts (pin 87 and pin 30) should close.

If none of the aforementioned tests identify the problem and the relay is in proper working order, replace the engine control unit.

Component replacement methods

No special measures are necessary in order to replace the injection relay.

Side stand button

Side stand button

Introduction

The side stand button is located on the side stand. Together with the signal

from the clutch button and the neutral signal

generated by the gear sensor (transmitted to the engine cont ...

Throttle valve actuator motor relay

Throttle valve actuator motor relay

Introduction

The throttle valve actuator motor is powered by the engine control unit. The

engine control unit receives the necessary

power from a specific relay.

Component assembling position

...

Other materials:

Removal of the primary drive gear

Withdraw the clutch housing (1) complete with driven gear of the primary pair

(a).

Remove the inner spacer (2).

Remove the oil pump (d) (sect. 9 - 2.1, Removal of the oil pump).

Lock the primary pinion (b) with the holding tool 88713.3417 And loosen the

threaded ring nut (3) u ...

Dtc (ducati traction control) setting function

This function allows you to customise the level of dtc

intervention (ducati traction control) or disable it for every

riding mode.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?" " sele ...

Front and rear mudguard

Front mudguard

Washer

Rivet

Clip

Screw

Spacer

Screw

Rear mudguard

Screw

Spare parts catalogue

Diavel abs rear swingarm

Diavel abs belly fairing

Diavel carbon

abs

rear swingarm

Diavel carbon

abs

belly fairing

Important

Bold reference numbers in this section identif ...