Ducati Diavel Service Manual: Inspection of the gear selector drum

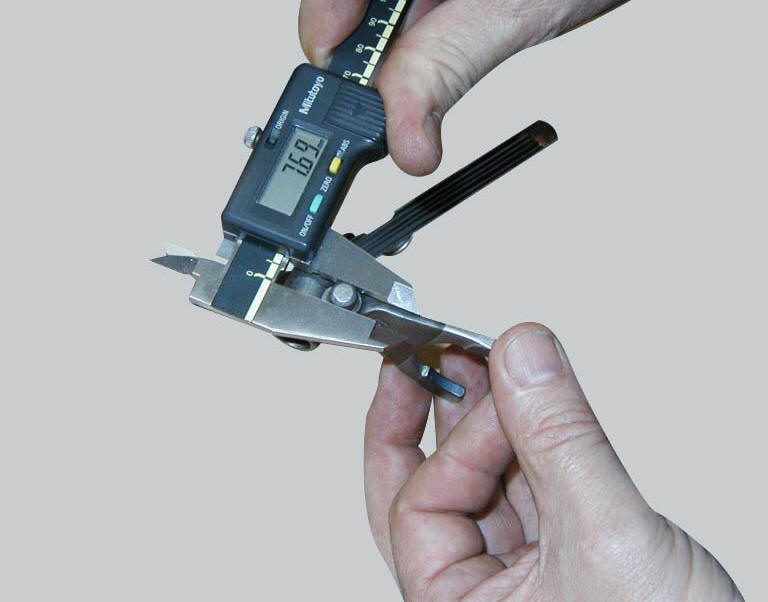

Use a gauge to measure the clearance between fork pin and the slot on the selector drum.

If the service limit is exceeded, determine which part must be replaced by comparing these dimensions with those of new components (sect. 3 - 1.1, Gearbox).

Also check the wear on the drum support pins; these must not show any signs of scoring, burrs, or deformation.

Turn the drum in the crankcase to establish the extent of radial play. If play is excessive, change whichever part is most worn.

Inspection of the gear selector forks

Inspection of the gear selector forks

Visually inspect the gear selector forks. Bent forks must be renewed as they

may lead to difficulties in gear changing or

may suddenly disengage when under load.

Use a feeler gauge to check the ...

Reassembly of the gearbox shafts

Reassembly of the gearbox shafts

Figure 1 shows all the parts to be reassembled on the gearbox primary shaft

(2), with the calculated end shims (1) and

(11) (sec. 9 - 9.2, Reassembly of the crankcase halves).

Figure 2 shows a ...

Other materials:

Refitting the seat

Note

Apply recommended grease to the hole (a) of latch (6).

Fit the seat (1) as follows: insert the tabs (b) (on the front side) under

the rubber pads (c) of the gloves compartment;

then push the seat rear side until hearing the lock latch click.

...

Filling the clutch circuit

Warning

Clutch fluid will damage painted surfaces if spilled on them. It is

also very harmful if it comes into contact with the skin or

with the eyes; in the case of accidental contact, wash the affected area

thoroughly with plenty of running water.

Remove cover (1) and membrane from the clut ...

Traction control (dtc) deactivated

The activation of this (amber yellow) "warning" indicates

that dtc (ducati traction control) has been turned off.

Note

In this case, ducati recommends being very careful

when riding as the vehicle behaviour will be different in

comparison to when operating with the traction control

...