Ducati Diavel Service Manual: Inspection of the gear selector forks

Visually inspect the gear selector forks. Bent forks must be renewed as they may lead to difficulties in gear changing or may suddenly disengage when under load.

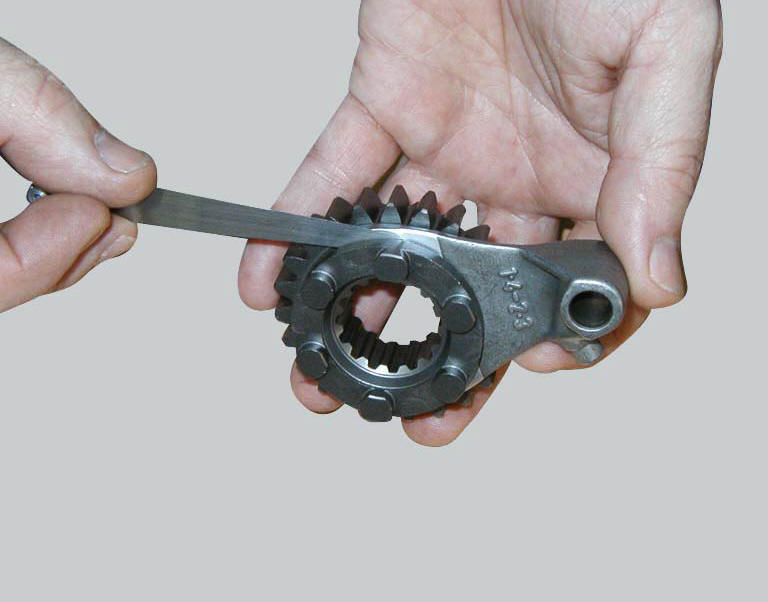

Use a feeler gauge to check the clearance of each fork in its gear groove.

If the service limit has been exceeded, check whether or not it is necessary to replace the gear or the fork by referring to the limits specified for each part (sect. 3 - 1.1, Gearbox).

Overhaul of the gearbox

Overhaul of the gearbox

Check the condition of the front coupling dogs of the gears. They must be in

perfect condition and with no sign of wear on

the edges of the teeth.

The idler gears must rotate freely on their sha ...

Inspection of the gear selector drum

Inspection of the gear selector drum

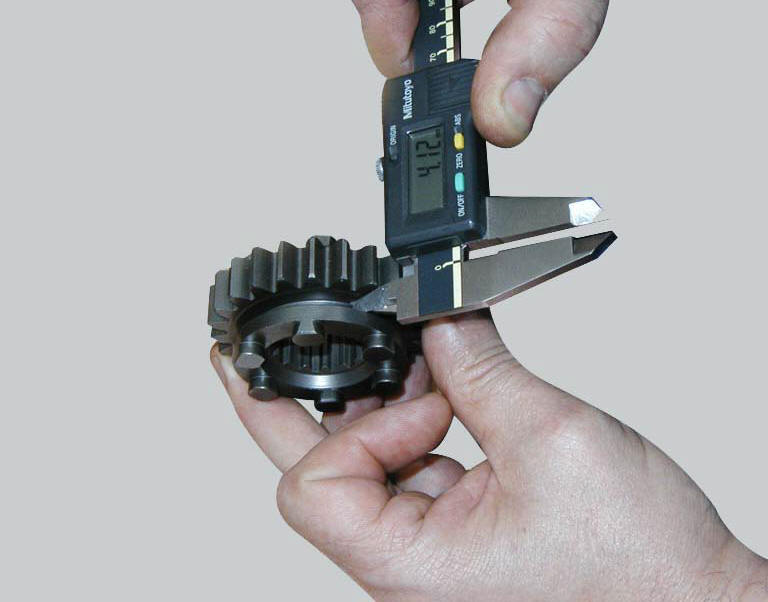

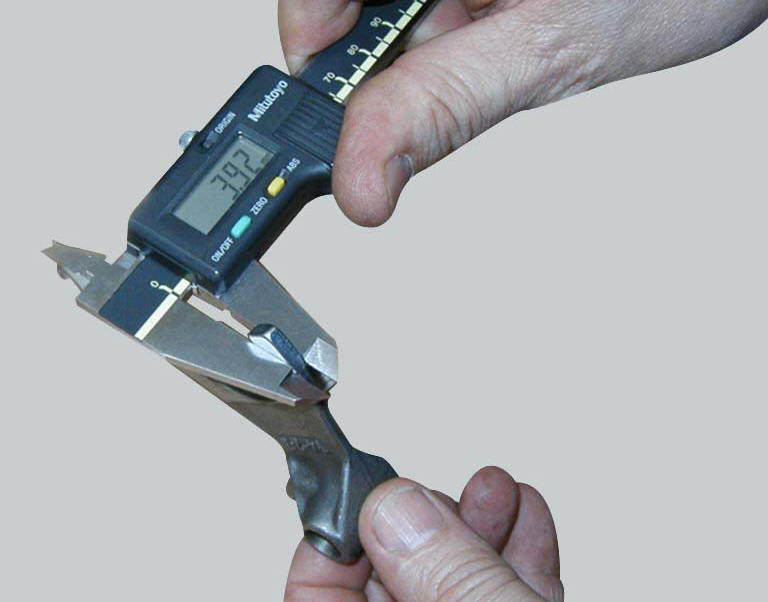

Use a gauge to measure the clearance between fork pin and the slot on the

selector drum.

If the service limit is exceeded, determine which part must be replaced by

comparing these dimensions wi ...

Other materials:

Refitting the cylinder head assemblies

Warning

To prevent oil leaks past the contact area between cylinders and

crankcase, each time the head is removed, cylinder and

piston must be removed as well to clean the mating faces of crankcase and

cylinder and restore the spoiled gaskets and

o-rings and apply again liquid sealant (sect. ...

Operations to be carried out by the dealer

List of operations to be performed at 1000 km

Reading of the error memory with dds on the engine control units,

vehicle and abs

Change the engine oil

Change the engine oil filter

Check the indicators and lighting

Check the safety devices (side ...

Refitting the gear interlock plunger and pawl assembly

On the special screw (3), fit the gear pawl lever (4), orienting it as shown

in the figure, the washer (2) with the square

edge side (d) facing the clutch-side crankcase half, and the spring (1),

positioning it so that the hook end (a) is facing

the gear pawl lever. Locate the hook end (a) of ...