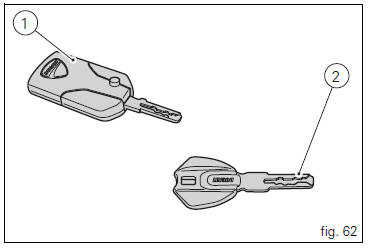

Ducati Diavel Owners Manual: Keys (fig. 62)

The owner receives a set of keys comprising:

- 1 Active key (1, fig. 62)

- 1 Passive key (2, fig. 62)

It contains the code used by the "hands free" system for the key-on, in different modes.

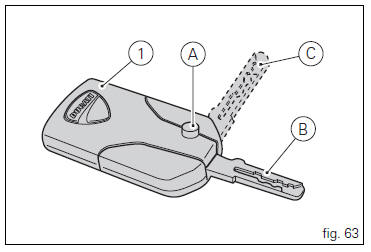

The active key (1, fig. 63) Is the one that is normally used: press button (a, fig. 63) To fully open the metal part, i.E.

Position (b, fig. 63). Holding depressed button (a, fig. 63) You can move the metal part and set it to the middle position (c, fig. 63); Once in place, release button to lock.

The metal part returns inside the grip by pushing it in.

The key contains a battery that must be replaced when the low key battery "warning" is displayed as soon as the instrument panel is turned on (fig. 64).

Note

Note

In this case, replace the battery as soon as possible (page 88).

When the charge level goes below a certain limit, the key can only work in passive mode, like the passive key: in this case, the instrument panel will not display any message.

Warning

Warning

Do not ride with the key (1 or 2, fig. 62) Inserted in the lock of the tank cap or in the seat lock as it could come out and represent a potential danger. Furthermore, if bumped, the key mechanism and the integrated circuit could be damaged.

Also riding in poor weather conditions with the key inserted could cause damage to its integrated circuit.

Do not leave the key on the motorcycle when washing it as it could be damaged, not being watertight.

The immobilizer system

The immobilizer system

For additional antitheft protection, the motorcycle is

equipped with an immobilizer, an electronic system that

locks the engine automatically whenever the ignition switch

is turned off.

The grip ...

Replacing the battery in the active key

Replacing the battery in the active key

Only use 3 volt cr 2032 lithium ion batteries.

Note

The keys do not need to be reprogrammed after

replacing the battery.

Remove the metal part of the battery.

Use a large sized coin to pry ope ...

Other materials:

Suspensions

Front

Hydraulic upside-down fork provided with external adjusters

for rebound and compression damping and preload (for inner

springs of fork legs).

Stanchion diameter:

50 mm, coated.

Rear wheel travel:

120 mm

Rear

The shock absorber is adjustable for rebound and

compression, with remot ...

Adjusting the chain tension

Make the rear wheel turn until you find the position where chain is tightest.

Set the vehicle on the side stand. Push down

the chain at the point of measurement and release. Measure the distance between

the "aperture" upper profile and pin

centre.

The read distance must be: 9 to 11 mm.

...

System components

Screw

Abs front speed sensor

Sealing washer

Hose grommet

Abs rear speed sensor

Abs control unit

Front pump - control unit pipe

Control unit - front callipers pipe

Rear pump - control unit pipe

Control unit - rear calliper pipe

Sealing washer

Support

Spacer

Rubber mou ...