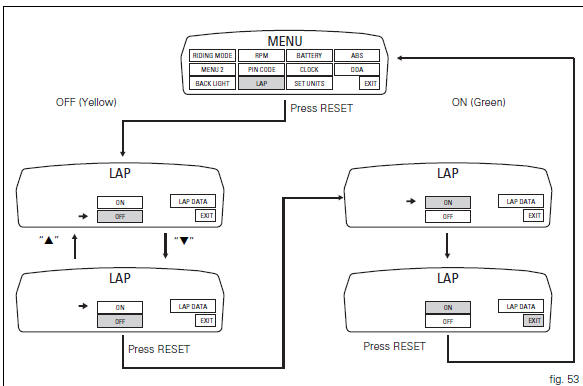

Ducati Diavel Owners Manual: Lap activation/deactivation function (lap time)

This function activates and deactivates the lap function (lap time).

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"

" or (2, fig. 14) ?" " select the "lap" function and

" select the "lap" function and

press the reset button

(12, fig. 12) To go to next page.

Function state is highlighted on the display (on in green or off in yellow); use

button (1, fig. 14) ?"

" or (2, fig. 14) ?" "

"

to shift the arrow on the left onto the new setting and

confirm by pressing the reset button (12, fig. 12).

To exit the setting function, press the reset button (12, fig.

12) Where "exit" is highlighted.

Storing the "off" condition disables the lap function.

Storing the "on" condition enables the lap function (see "lap registration" paragraph).

Note

Note

When the "lap" function is active, the flash button (11, fig. 12) Takes on the dual function of high beam headlight "flash" and lap time start / stop.

Digital rpm indication function

Digital rpm indication function

This function displays the number of rpms for improved

accuracy when setting idle rpm.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. ...

Lap registration function

Lap registration function

This function describes the "lap" time registration.

If the function is activated (see "lap activation/deactivation

description), the lap time can be registered as follows:

Pres ...

Other materials:

Riding mode set indication

This function indicates the "riding style" set for the vehicle.

Three "riding modes" are available: sport, touring and

urban.

Each riding mode can be changed using the "riding

mode" function.

Note

The background of the riding mode (sport, touring

or urban) i ...

Refitting the gearchange mechanism

Make sure that the gearchange linkage assembly (6) is installed with the ball

joint with a left-hand thread (a) facing the

lever (8).

Apply the recommended grease to the non-threaded surface of the pin (4).

Fit the first o-ring (5) in the pin (4).

Start the pin (4) in the gearchange leve ...

Chain lubrication

The chain fitted on your motorcycle has o-rings that keep dirt

out of and lubricant inside the sliding parts.

So as not to damage these seals when cleaning the chain,

use special solvents and avoid aggressive washing with highpressure

steam cleaners.

After cleaning, blow the chain dry with ...