Ducati Diavel Service Manual: Lap registration function

This function describes the "lap" time registration.

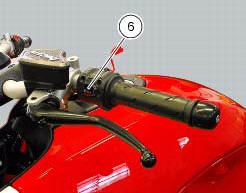

If the function is activated (see "lap activation/deactivation description), the lap time can be registered as follows: pressing the flash headlight button (6) the first time starts the "lap timer" for the first lap, and the dashboard shows the message "lap-start" flashing for 4 seconds, and then returns to the "previous" display; from this moment, each time that the flash (6) is pressed the display automatically shows the lap number and lap time for 10 seconds and then returns to the "previous" display.

You can save a maximum of 30 laps in the memory.

Once the memory is full, the dashboard no longer stores lap times when the flash headlight button (6) is pressed, and the flashing message "lap-full" is shown on the display for 4 seconds until the times are reset.

When the lap function is set disabled, the current "lap" is not stored.

If the lap function is active and suddenly the motorcycle is suddenly turned off (key-off), the function will be automatically disabled (even if the lap timer was active, the current "lap" is not stored).

If the time is never "stopped", it will roll over upon reaching 9 minutes, 59 seconds and 99 hundredths; the lap timer starts counting from 0 (zero) and will keep running until the function is disabled.

If however the lap function is switched on and the memory has not been cleared, but fewer than 30 laps have been saved (e.G. 18 Laps), the dashboard will store any remaining laps until the memory is full (in this case, it will store an additional 12 laps).

This function only displays the times for the lap being registered; but other data are also saved (max speed and max rpm) for viewing at a later date in the "lap data" function (stored lap display).

Lap activation/deactivation function (lap time)

Lap activation/deactivation function (lap time)

This function activates and deactivates the lap function (lap time).

To access the function it is necessary to view the ""setting" menu", using

buttons (1) "s" or (2) "t" select the "lap"

functi ...

Stored lap display function

Stored lap display function

This function displays the stored laps.

To access the function it is necessary to view the ""setting" menu", using

buttons (1) "s" or (2) "t" select the "lap"

function and press the reset button ...

Other materials:

Checks and adjustments

Closing shim

Intake side camshaft

Opening shim

Exhaust side camshaft

Valve

Spare parts catalogue

Diavel abs cylinder head: timing system

Diavel abs vertical cylinder head

Diavel abs horizontal cylinder head

Diavel carbon

abs

cylinder head: timing system

Diavel carbon

abs

v ...

Disassembly of the oil pump

Hold the oil pump (1) in a vice taking care not to damage the drive gear

(12).

Warning

Make sure that vice jaws are faced with soft material.

Remove the plug (14) and extract the spring (16) and by-pass valve (17).

Check the condition of the above components.

Remove the circlip (6) ...

General maintenance indications

Useful tips

Ducati recommends that you follow the instructions below in order to prevent

problems and obtain the best end result:

When diagnosing faults, primary consideration should always be given to

what the customer reports about motorcycle

operation since this information can highli ...