Ducati Diavel Service Manual: Low beam lights not working

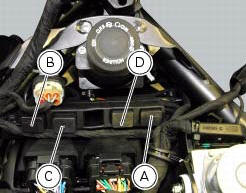

Location of connections and components

(A) injection relay; (b) etv relay (throttle valve operating engine); (c) radiator fan relay; (d) hands free relay.

Fuses located at the rear left of the vehicle.

(1) 10A dashboard; (2) 5a engine control unit; (3) 15a key-sense; (4) 20a injection relay; (5) 10a throttle opening relay (etv).

Fuses located at the rear right of the vehicle.

(1) 7.5A black box system (bbs); (2) 7.5A navigator/alarm; (3) 25a abs 2; (4) 30a abs 1; (5) 10a fans; (6) 7.5A diagnosis/recharge.

(A) low / high beam and parking light connections

High beam lights not working

High beam lights not working

Fault codes

The hi beam light on the (slave) dashboard flashes at 1hz frequency.

Wiring diagram

Location of elements on motorcycle

(A) injection relay; (b) etv relay (throttle valve operating ...

Horn not working

Horn not working

Fault codes

Dds: horn diagnosis -> short circuit to ground (s.C. Gnd).

Dashboard: the error "claxon" (horn) is shown on the service display. The eobd

warning light activates.

Wiring diagram

...

Other materials:

Adjusting the clutch lever and front brake lever

The clutch lever (1) is fitted with a span adjuster (2) which serves to alter

the distance of the lever from the handlebar.

The lever distance can be adjusted through 10 clicks of the dial (2). Turn

clockwise to increase lever distance. Turn the

adjuster counter clockwise to decrease lever d ...

Fault indication

The dds (diagnosis ducati system) indicates all active errors and all

inactive but stored errors gathered by the bbs. A

simplified summary of the active errors is also shown in the master dashboard

service display when the dashboard is

switched on. Simultaneously, the eobd warning light is als ...

Indicator cons. - Instantaneous fuel consumption

This function indicates the "instantaneous" fuel consumption.

The calculation is made considering the quantity of fuel used

and the distance travelled during the last second. The datum is

expressed in "l/100" (litres / 100 km); it is possible to change

the units of measurem ...