Ducati Diavel Service Manual: On/off switch on handlebar

Introduction

The on/off switch on the handlebar is used to switch the dashboard on and off, if a key has been detected, and start the engine.

With the switch turned to "run off" (centre position), pushing downwards switches the dashboard on or off (activating the button inside the switch).

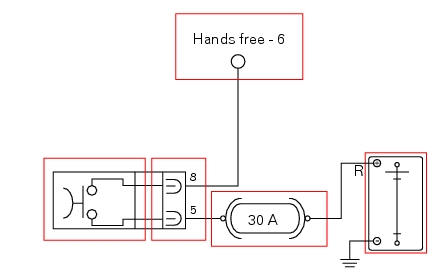

Wiring diagram

The button inside the on/off switch receives 12 volt power directly from the battery via the main 30 a fuse. When pressed, it sends the 12 volt power to the hands free system, which detects activation of the button. On/off switch pin 8, light blue wire (lb), on/off switch pin 5, red wire (r).

Pinout of right hand handlebar switch connection, wiring harness side.

Location of the right hand handlebar switch connection.

Error codes

The hands free system generates no fault code in the event of a fault of the on/off switch on the handlebar.

Electrical characteristics and checking component

The switch receives 12 volt power directly from the battery via the main 30 a fuse.

Check for 12 volts on pin 5 of the switch.

Check for 12 volts on pin 6 of the hand free system side connector with the switched pressed. The voltage measured must be 0 volts when the switch is not pressed.

In the event of fault

In the event of a fault of the on/off switch on the handlebar, the button integrated into the hands free system may be used instead.

Installation location

The image shows the location of the on/off switch, near the throttle grip on the right hand side of the handlebar.

Communication antenna

Communication antenna

Introduction

The communication antenna enables the hands free system to detect and

communicate with the active or passive key.

The active key is detectable within a range of 1.5 Metres, whereas ...

The hands free relay

The hands free relay

Introduction

This relay provides key on +15 power to all the devices on the motorcycle.

Functionally, it replaces the conventional

ignition switch.

Wiring diagram

The hands free relay receiv ...

Other materials:

Indicator trip time - trip time

This function shows the vehicle trip time.

The calculation is made considering the time travelled since

the last trip 1 reset. When trip 1 is reset, the value is set to

zero.

The active phase calculation occurs when the engine is

running and the vehicle is stopped (when the vehicle is not

...

Refitting the clutch-side crankcase cover

Clean and degrease mating surfaces on the clutch-side crankcase half cover

and crankcase and ensure that locating bush

(12) and the o-ring (11), located in correspondence with the oil way, are

installed in the crankcase.

Apply an even, regular bead of ducati liquid gasket (a) on the mating ...

Removal of the fuel tank

On the usa version remove the canister filter as indicated in sect. 8 - 10,

"Removal of the evaporative emissions

canister".

Loosen and remove the front retaining screw (4)

Remove the flange cover (a) by loosening the screws (b), disconnect the

quick-release fittings (c) from the fl ...