Ducati Diavel Service Manual: Overhauling the front wheel

Wheel bearings

Before checking the dimensions, check the wear on wheel bearings. Check for wear by hand after cleaning and degreasing the bearings in their seats.

Turn the inner race.

Check the amount of radial and axial play. Excessive play will cause vibration and make the bike unstable.

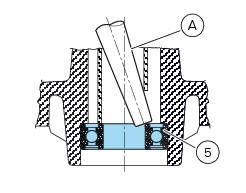

To remove the bearings (5) and the sealing rings (4) from the wheel hub follow the instructions below.

Position a drift (a) against the inner race of the bearing (5).

Tap with a hammer until knocking out the bearing (5).

Apply the drift at different points to keep the bearing square during removal.

Important

Once removed, the used bearings and sealing rings must not be refitted.

Before fitting new bearings, check that the housing is clean and free from scoring and damage.

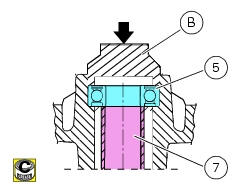

Grease the bearing seat and then push the new bearing into its seat.

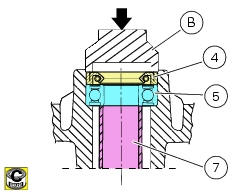

Using a tubular drift (b) that only bears on the outer race of the bearing, drive the bearing (5) fully into its seat.

Use the same method to install the sealing rings (4).

Ensure that spacer (7) is fitted between the two wheel bearings.

Note

Wheels must be rebalanced after repair, maintenance and overhaul operations.

Inspecting the wheel axle

Check the wheel shaft for straightness.

Turn the pin on a reference surface and measure maximum distortion using a feeler gauge (see sect. 3 - 1.1, Front wheel).

Overhauling the wheel

After you have checked the bearings, check the rim as follows.

Visually inspect the wheel for cracks, scoring and deformation; change the wheel if damaged.

Insert the shaft in the wheel and mount it on two fixed reference blocks.

Using a dial gauge, measure rim run-out and out-of-round relative to the pin axle (see sect. 3 - 1.1, Front wheel).

If the values measured are not within the tolerance limits, renew the wheel.

Removal of the front wheel

Removal of the front wheel

Support the bike so that the front wheel is raised from the ground.

Remove the front brake calliper (b) by unscrewing the two screws (a) securing

the calliper to the fork leg; do not

disconnect ...

Refitting the front wheel

Refitting the front wheel

When all the necessary inspections have been completed, refit the wheel as

follows.

Fit the spacers (3) and (9) to the seal rings on the sides of the wheel hub.

Install the complete whee ...

Other materials:

Throttle valve actuator motor relay

Introduction

The throttle valve actuator motor is powered by the engine control unit. The

engine control unit receives the necessary

power from a specific relay.

Component assembling position

A injection relay; b etv relay (throttle valve actuator motor), c radiator

fan relay, d engine c ...

Low beam lights not working

Location of connections and components

(A) injection relay; (b) etv relay (throttle valve operating engine); (c)

radiator fan relay; (d) hands free relay.

Fuses located at the rear left of the vehicle.

(1) 10A dashboard; (2) 5a engine control unit; (3) 15a key-sense; (4) 20a

injecti ...

On-board computers and the can line

The following on-board computers make up the electrical system of the diavel

and are connected with each other via the

can line (or network):

Master dashboard

Slave dashboard

Hands free (facilitated keyless start system)

Ecu (engine control unit)

Bbs (black box system or central elect ...