Ducati Diavel Owners Manual: Pre-ride checks

Warning

Warning

failure to carry out these checks before riding, may lead to motorcycle damage and injury to rider and passenger.

Before riding, perform a thorough check-up on your bike as follows:

Fuel level in the tank

Check the fuel level in the tank. Fill tank if needed (page 140).

Engine oil level

Check the oil level in the sump through the sight glass.

Top up if needed (page 164).

Brake and clutch fluid

Check fluid level in the relevant reservoirs (page 143).

Coolant level

Check coolant level in the expansion reservoir.Top up if needed (page 142)

Tyre condition

Check tyre pressure and condition (page 162).

Controls

Operate the brake, clutch, throttle and gear change controls (levers, pedals and twistgrip) to check that they function correctly.

Lights and indicators

Make sure the lights, indicators and horn work properly.

Replace any burnt-out bulbs (page 158).

Key-operated locks

Ensure that fuel filler plug (page 118) and seat (page 119) are firmly secured.

Stand

Make sure side stand operates smoothly and is in the correct position

Abs light

After key-on, the abs light (9, fig. 4) Stays on. When the vehicle speed exceeds 5 km/h; the light turns off to indicate that the abs system is functioning properly.

Warning

Warning

In case of malfunction, do not ride the motorcycle and contact a ducati dealer or authorised service centre.

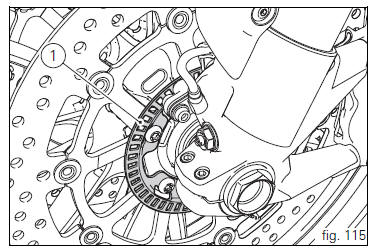

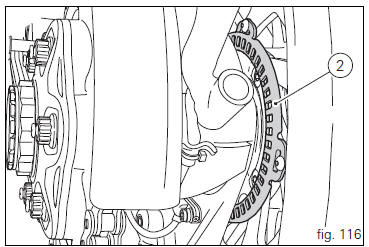

Abs device

Check that the front (1, fig. 115) And rear (2, fig. 116) Phonic wheels are clean.

Warning

Warning

Clogged reading slots would compromise system proper operation.

It is recommended to disable abs system in case of muddy road surface because under this condition the system might be subject to sudden failure.

Warning

Warning

Prolonged rearing could deactivate the abs system.

Running-in recommendations

Running-in recommendations

Maximum rpm (fig. 114)

Rotation speed for running-in period and during standard use

(rpm)

Up to 1000 km;

From 1000 to 2500 km.

Up to 1000 km

During the first 1000 km, keep an eye on the re ...

Engine on/off

Engine on/off

Warning

Before starting the engine, become familiar with the

controls you will need to use when riding (page 99).

Warning

Never start or run the engine indoors. Exhaust gases

are toxic and may ...

Other materials:

Removal of the timing belt covers

Loosen the screws (4) securing the central external cover (1) and remove it

from the central side.

Undo the fixing screws (4) of the external cover (25) and remove it from the

vertical thermal unit.

Undo the fixing screws (4) of the external cover (3) and remove it from the

horizonta ...

Stored lap display function

This function displays the stored laps.

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"" or (2, fig.

14) ?" " select the "lap" function and

press the reset button

(12, fig. 12) To go to next pag ...

Removal of the front brake system

Note

For the abs front braking system, also refer to sect. 7 - 5, Abs system

operating information, sect. 7 - 6, System

components, sect. 7 - 7, Abs components maintenance.

Undo the special screw (3), collect the sealing washers (4), and release the

front brake master cylinder assembly (1 ...