Ducati Diavel Service Manual: Reassembling the clutch

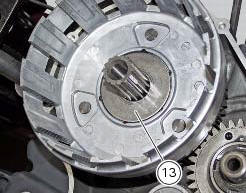

Position the spacer (13).

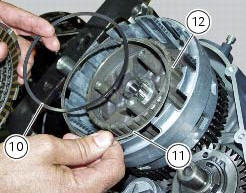

Fit the flat ring (11) and the belleville washer (10) on the clutch center (12), so that the convex side faces the clutch drum.

Locate the belleville washer (8).

Apply the prescribed grease to the thread of the gearbox primary shaft and the mating surface of nut (7), and fit it over belleville washer (8).

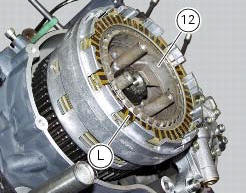

Lock the clutch center (12) by means of tool number 88713.3408 And tighten the retaining nut (7) to a torque of 190 nm (min. 180 Nm - max. 200 Nm) (sect. 3 - 3, Engine torque settings).

Install the clutch plates (9) in the following order: on the drum (12):

- A series of ten driving discs (l) alternately to new driven discs (i) thickness 2 mm;

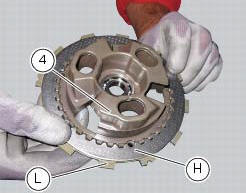

On the pressure plate (4):

- One driven disc (h), 2 mm thick;

- A driving disc (l).

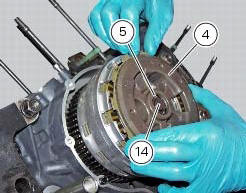

Insert the control pin (14) in the bearing (5) and the latter in the gearbox primary shaft.

Place the pusher plate (4) with the two discs on the centring tool part no. 88713.3352.

Fit the pressure plate (4).

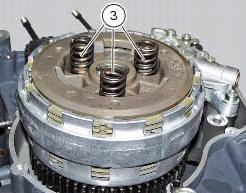

Insert a spring (3) in each slot.

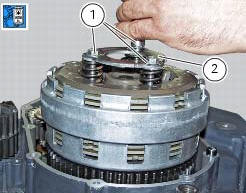

Position the o-ring (2).

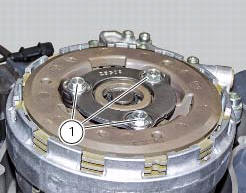

Lubricate the thread of the screws (1) with oil.

Insert the screws (1).

Tighten the screws (1) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Checking and overhauling the components

Checking and overhauling the components

Clearance between the clutch drum and friction plates

Insert a friction plate (e) in the clutch drum (f) and measure the clearance

(s) with a feeler gauge.

Clearance "s" must not exceed 0.6 Mm.

...

Clutch cover

Clutch cover

Clutch-side crankcase cover

Screw

Screw

Oil level sight glass

Screw

Plate

Bush

Sealing ring

Shim washer

Circlip

O-ring

Locating bush

O-ring

Plug

Sealing washer

Scr ...

Other materials:

Fuel tank

fuel tank

Rubber pad

Spacer

Screw

Hose

Tray

Y-fitting

Hose

Hose

Filler cap

Screw

Complete hose guide

Screw

Hose clip

Hose

Screw

Screw

Sealing washer

Screw

Flange

Sealing washer

Spare parts catalogue

Diavel abs fuel tank

Diavel abs fuel system

Diav ...

Low battery level

The activation of this (amber yellow) "warning" indicates that the status of

the battery vehicle is low.

It is activated when the battery voltage is ¼ 11.0 Volt.

Note

In this case, ducati recommends charging the battery as soon as possible

with the specific device, as it is possible th ...

Disassembly of rear shock absorber - rocker arm - linkage assembly

Undo the screw (15) and remove the rear shock absorber (11) from the rocker

arm (18).

Undo

Undo the screw (14) and the nut (21) and remove the linkages (10) and (12)

from the rocker arm (18).

The rocker arm movement is obtained by needle roller bearings (9) rotating on

a spacer (1 ...