Ducati Diavel Service Manual: Reassembly of belly fairing

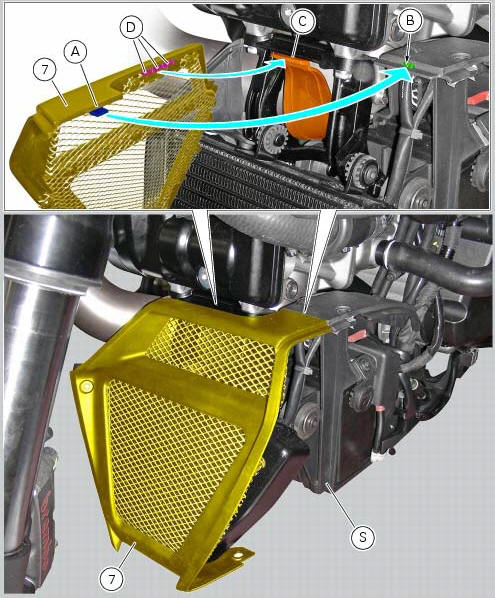

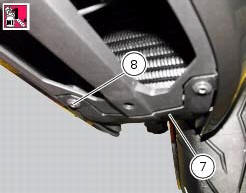

Position the oil cooler shield (7) inserting the tab (a) into the slit (b) in the electrical components support (s).

Note

On refitting, make sure that the tab (c) remains positioned under the retainers (d) of the shield (7).

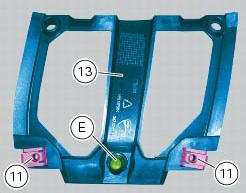

Fit clips (11) on bracket (13) and orient them as shown in the figure.

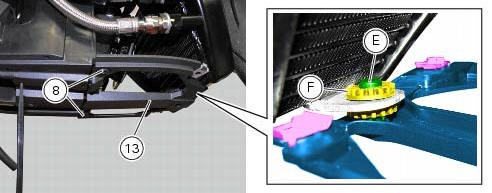

Apply rubber lubricant to the pin (e) of the bracket (13).

Insert pin (e) in the vibration damping pad (f) of the oil cooler.

Fit the bracket (13) on the electrical components support, and tighten the screws (8) to a torque of 4 nm +/- 10 % (sect. 3 - 3, Frame torque settings).

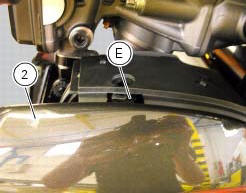

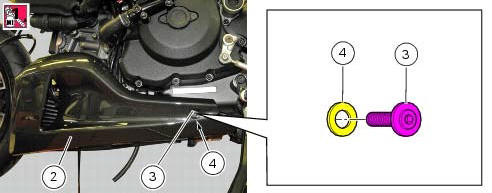

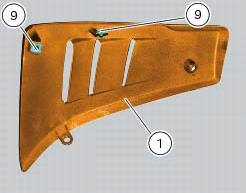

Fit clips (9) on lh belly fairing (2) and orient them as shown in the figure.

Put the lh belly fairing (2) in position by engaging slot (e) in the electrical components support, as shown in the figure.

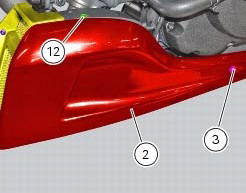

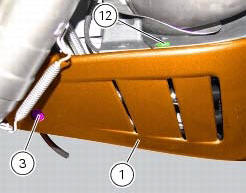

Apply recommended threadlocker on screws (3) and (12).

Fit the nylon washer (4) on the screw (3).

Fix the lh belly fairing (2) to the electrical components support by starting the screws (3) on the rear side, and the screw (12) on the upper side.

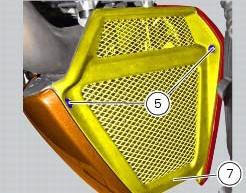

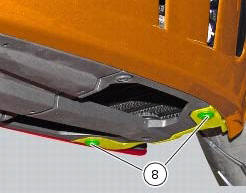

Apply recommended threadlocker to the screws (5) and (8).

Fix the lh belly fairing (2) to the oil cooler shield (7) by starting the screw (8) on the lower side, and the screw (5) on the front side.

Fit the clips (9) on the rh belly fairing (1) orienting it as shown in the figure; follow the same procedure to refit the lh belly fairing (2).

Tighten to a torque of 4 nm +/- 10% (sect. 3 - 3, Frame torque settings) the screws (3), (5), (8) and (12) to fix the belly fairings (1) and (2) and the oil cooler shield (7).

Removal of belly fairing

Removal of belly fairing

Loosen and remove the screws (5) and (8) that secure the oil cooler (7) to

the rh (1) and lh (2) belly fairings.

Remove the lh belly fairing (2) by loosening the screws (3) with relevan ...

Electrical components support

Electrical components support

Clip

Screw

Voltage regulator

Battery fixing bracket

Battery support

Vibration damper mount

Hose clip

Vibration damper mount

Clip

Washer

Screw

Cover

Cable grommet

Batte ...

Other materials:

Checking the engine timing

Set the engine to the configuration described for the "checking and adjusting

the valve clearances", previously indicated.

Install tool 88765.1188 (G) in the spark plug bore to determine the piston tdc,

the gauges (h) on the tool 88765.1518

And the timing check tool (degree wheel (l) 887 ...

Tips for use on the track

We recommend level 8 be used for a couple of full laps (to

allow the tyres to warm up) in order to get used to the

system. Then try levels 7, 6, etc., In succession until you

identify the dtc intervention level that suits you best (always

try each level for at least two laps to allow the tyres t ...

Removing the valves

Raise the rocker arm (3) and remove the opening shim (5) from the valves with

a pair of pliers.

Push down the closing rocker arms (16) and (4) and the closing shim (7).

Remove the half rings (6) from the valves with a magnetic screwdriver. Extract

the closing shims (7) from the valve ...