Ducati Diavel Service Manual: Reassembly of the crankcase halves

The crankcase halves must be in good condition and perfectly clean. The mating surfaces must be perfectly flat and free from burrs.

Overhauling the alternator-side crankcase half

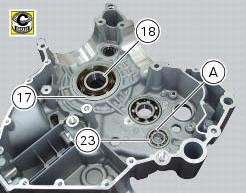

The following parts must be present on the internal side of the crankcase half:

- Gearbox secondary shaft bearing (23): apply grease to the bearing rollers. Fit the inner race (a) removed previously from the bearing. Apply grease to the inner ring;

- The primary shaft bearing (28), secured with screws (20) and retaining spacer (21): apply prescribed threadlocker to the screws (20) and tighten them to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings);

- The main bearing (18) with the corresponding bushing (17) (if present).

The roller bearing (15) with retaining circlip (16) installed in correspondence with the end of the timing belt driveshaft.

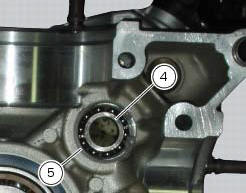

Insert the circlip (5) in the crankcase half installing it in its seat on the bearing (4).

Refitting the alternator-side crankcase half

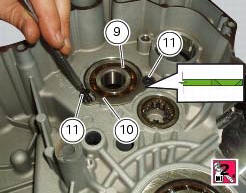

The following parts must be present on the internal side of the crankcase half: the double race ball bearing (9) supporting the selector fork shaft. Apply threadlocker to the screws (11). Fit the retaining plate (10) to the gearbox secondary shaft bearing (9) screwing the screws fully into the chain-side crankcase half (11).

Note

The bearing retaining plate must be positioned so that the countersunk side is facing upwards.

Tighten the screws (11) to a torque of 10 nm (min. 9 Nm - max. 11 Nm) (sect. 3 - 3, Engine torque settings).

Lubricate the ring (6) with denatured alcohol, drive it fully home against the crankcase half, and orient it as shown.

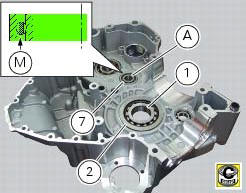

The primary shaft bearing (7) with internal spacer (6), oriented so that the closed side of the plastic roller cage (m) faces The crankcase half: apply grease to the bearing rollers. Fit the inner race (a) removed previously from the bearing. Apply grease to the inner race.

The main bearing (1) with the corresponding bushing (2) (if present).

The bearing (4) with the retaining circlip (5) installed in correspondence with the timing belt driveshaft.

Insert the circlip (5) in the crankcase half installing it in its seat in the crankcase half on the bearing (4).

Note

Bearings do not have a specific mounting position (except main bearings); however it is good practice to install the bearings so that side bearing the writing is facing upwards.

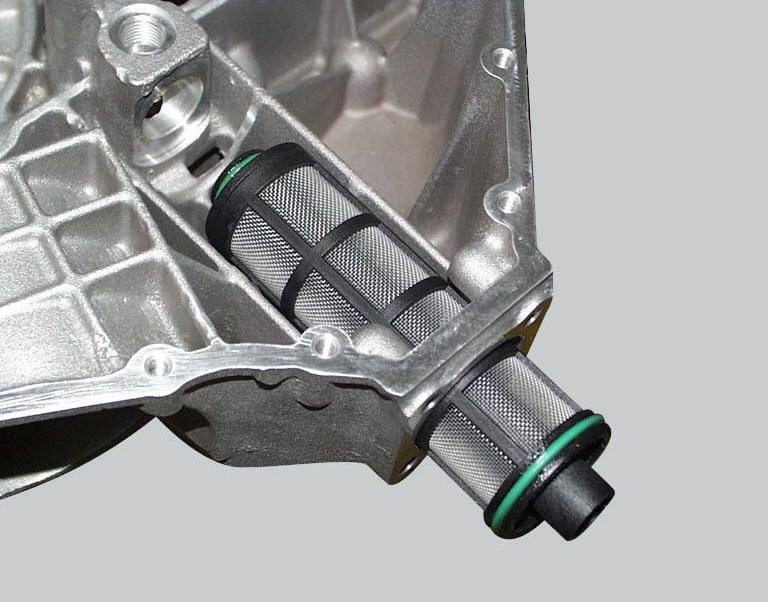

Fit the mesh filter as described in sect. 4 - 3, Changing the engine oil and filter cartridge.

Important

To avoid damaging the filter, insert it by hand only. Do not use hammers or other metal tools.

Above the mesh filter seat there is a plug (19) which closes off the lubrication oilway. If it is to be renewed, apply the prescribed threadlocker to its threads.

Tighten the plug to a torque of 24 nm (min. 21 Nm - max. 27 Nm) (sect. 3 - 3, Engine torque settings).

Main bearings

Main bearings

The main bearings have are of the angular contact type with offset inner

races so that the balls transmit loads from one

groove to the other along straight lines at an angle to the axis of the bear ...

Shimming the shafts

Shimming the shafts

Before assembling the crankcase halves, calculate the shims required to

obtain the correct end float of the crankshaft and

gearbox shafts.

To determine the correct shim thickness proceed as foll ...

Other materials:

Shimming the shafts

Before assembling the crankcase halves, calculate the shims required to

obtain the correct end float of the crankshaft and

gearbox shafts.

To determine the correct shim thickness proceed as follows.

Shimming the crankshaft

After having installed the new main bearings (with bushing (a) or ...

Reassembly of the connecting rods

Before starting, check that the crankshaft main bearing journals and big-end

journals are free of burrs or evident signs of

machining: if necessary, clean the surfaces with very fine emery cloth and oil.

Check that the grooves are in perfect condition with no signs of forcing.

Clean the cra ...

Warning indication (alarms/signals)

The instrument panel activates in real-time some warnings /

malfunction that are not dangerous for the correct operation

of the vehicle.

At key-on (at the end of the check) one or more "warnings"

are displayed if they are active.

When a "warning" is triggered, the indica ...