Ducati Diavel Service Manual: Reassembly of the gearbox shafts

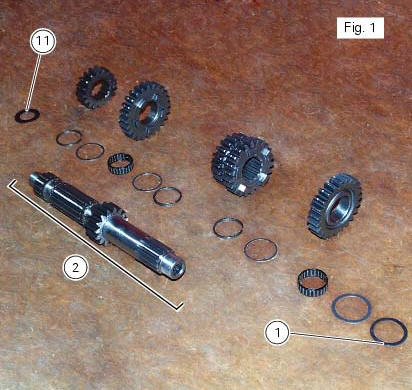

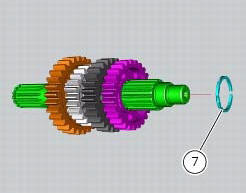

Figure 1 shows all the parts to be reassembled on the gearbox primary shaft (2), with the calculated end shims (1) and (11) (sec. 9 - 9.2, Reassembly of the crankcase halves).

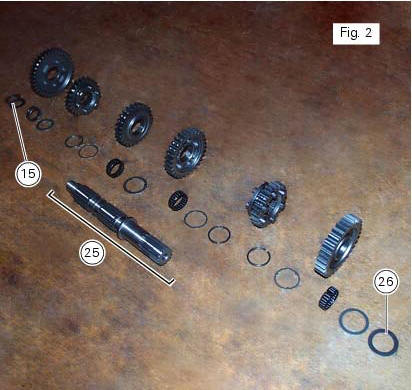

Figure 2 shows all the parts to be installed on the gearbox secondary shaft (25), with calculated end shims (15) and (26) (sec. 9 - 9.2, Reassembly of the crankcase halves).

Reassemble the gears on the gearbox shafts by reversing the disassembly procedure.

Take particular care when installing the idler gears. The assembly of the 3rd and 4th speed gears and the relative fixing components on the secondary shaft is given as an example.

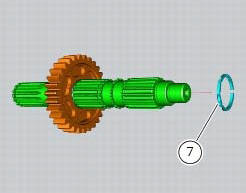

Fit the circlip (7), checking that it is fully inserted into its groove on the shaft. Push the circlip into position with a suitable size tubular drift.

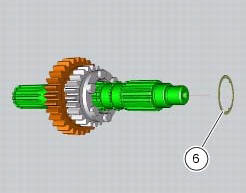

Slide the washer with three internal points (6) over the shaft until it locates against the circlip you have just fitted.

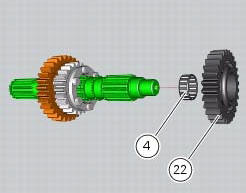

To fit the needle roller cage (4) onto the shaft, first lubricate it with plenty of grease (of recommended type) and then open it slightly to make it easier to slide on to the shaft.

Fit the 3rd speed gear (22).

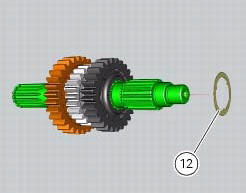

Fit on the gear the three-pointed washer (12), which can be distinguished from its counterpart (6) by its bigger outside diameter.

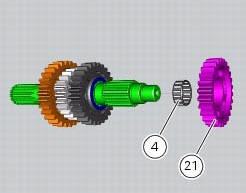

Fit another needle roller cage (4) using the method already described.

Fit the 4th speed gear (21).

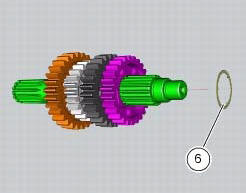

Fit another safety washer (6) and another circlip (7) into the shaft. Push it inside its seat using the previously used pad.

Inspection of the gear selector drum

Inspection of the gear selector drum

Use a gauge to measure the clearance between fork pin and the slot on the

selector drum.

If the service limit is exceeded, determine which part must be replaced by

comparing these dimensions wi ...

Reassembly of the gearbox

Reassembly of the gearbox

To refit the gearbox components follow the procedure under sect. 9 - 9.2,

Reassembly of the crankcase halves, relating to

reassembly of the engine crankcase.

As a final practical test, ensure th ...

Other materials:

Refitting the oil pump

If removed, apply specific threadlocker on the bushing (7) outer thread, and

screw it in the crankcase half, observing the

height.

Position the reference bushings (15) and the oil sealing o-rings (2) and (4)

according to the crankcase lubrication

channels.

Position the oil pump on th ...

Disassembly of the clutch cover

Remove the plug (14) and its o-ring (13), the plug (17) and its o-ring (15)

from the cover.

Undo the fixing screw (16) of the inner cover (19).

Remove the inner cover (6) and soundproofing panel (18).

Remove the circlip (10) and withdraw the shim (9) and the sealing ring (8).

The dri ...

Rectifier-regulator

The rectifier (1) is placed in the electrical components compartment.

The rectifier/regulator consists of an aluminium casing containing the diodes

that rectify the current produced by the

alternator. It also contains an electronic device that regulates the current

supplied by the alternator ...