Ducati Diavel Service Manual: Reassembly of the oil pump

Check that the circlip (3) and tongue (13) are present on the pump.

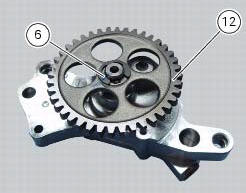

Fit the pump drive gear (12) on to the oil pump and secure it by installing the circlip (6) in its groove.

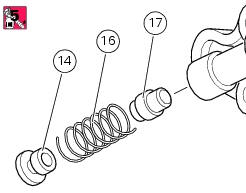

Insert the by-pass valve pump (17), the spring (16) and screw the plug (14). Tighten the plug (14) to a torque of 17 nm (min. 15 Nm - max. 19 Nm) (sect. 3 - 3, Engine torque settings) applying a medium strength threadlocker.

Disassembly of the oil pump

Disassembly of the oil pump

Hold the oil pump (1) in a vice taking care not to damage the drive gear

(12).

Warning

Make sure that vice jaws are faced with soft material.

Remove the plug (14) and extract the spring (16) ...

Refitting the oil pump

Refitting the oil pump

If removed, apply specific threadlocker on the bushing (7) outer thread, and

screw it in the crankcase half, observing the

height.

Position the reference bushings (15) and the oil sealing o-ri ...

Other materials:

Shimming the shafts

Before assembling the crankcase halves, calculate the shims required to

obtain the correct end float of the crankshaft and

gearbox shafts.

To determine the correct shim thickness proceed as follows.

Shimming the crankshaft

After having installed the new main bearings (with bushing (a) or ...

Technical specifications

General

Colours

Transmission

Timing system/valves

Crankshaft

Cylinder/piston

Gearbox

Cooling system

Front wheel

Front suspension (diavel abs)

Front suspension (diavel carbon abs)

Rear wheel

Rear suspension (diavel abs)

Rear suspensio ...

Inspecting the final drive

To check the wear of the final drive, visually check the pinion (14) and

sprocket (17). If the teeth are found to worn as

shown in the figure (dotted line), the sprocket must be renewed.

To check the amount of wear on the chain (8), keep the chain taut and measure

16 links.

If the l ...