Ducati Diavel Service Manual: Reassembly of the tool tray

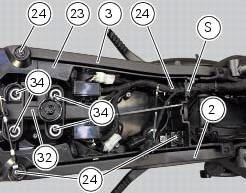

Place the tool tray unit (23) on the lateral brackets (2) and (3) by tightening the screws (24) to 14 nm +/- 5% (sect. 3-3, Frame torque settings).

If the handle guide (32) has been previously removed, position it on the tray (23) and tighten the screws (34) to 20 nm +/- 5% (sect. 3-3, Frame torque settings).

Reposition the wiring branch in the seat (s) in the tray (23).

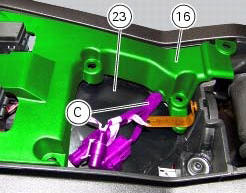

Place the gloves compartment cover (16) on gloves compartment (23), inserting wiring (c) into the suitable recess in the cover (16).

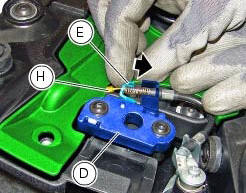

Warning

While positioning the cover (16) on the compartment (23), push bracket (e) of the lock latch (d) in the direction shown by the arrow, to prevent the lock wire terminal (h) from being squeezed under the cover.

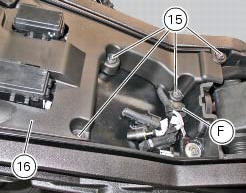

Check the presence of the clip (f) on the cover (16).

Fix the cover (16) by tightening the screws (15) to a torque of 4 nm +/- 10% (sect. 3 -3, Frame torque settings).

Apply the recommended threadlocker to the screws (40).

Reposition the splashguard (20) and tighten the screws (40) to a torque of 4 nm +/- 10% (sect. 3 -3, Frame torque settings).

Reassembling the frame and the lateral footrests

Reassembling the frame and the lateral footrests

Apply the recommended grease to the thread of the pins (9) and of the nuts

(8).

Place the frame (1) and the brackets (2) and (3) on the engine block. Start the

pins (9) by holding the nuts (8) ...

Tail light - number plate holder

Tail light - number plate holder

Rh tail light

Vibration damper mount

Spacer

Screw

Number plate light

Screw

Screw

Plate

Number plate holder

Nut

Screw

Rear chain guard

Lh tail light

Spring washer

Vib ...

Other materials:

Adjusting the steering head bearings

Excessive handlebar play or shaking forks in the steering head indicate that

the play in the steering head bearings

requires adjustment. Proceed as follows:

loosen the clamp screw (1) that holds the steering tube to the steering head.

Slacken the clamp screws (2) securing the steering head ...

Exhaust by-pass valve not working correctly

Fault codes

Dds: exvl diagnosis -> position error, potentiometer, short circuit to ground

or open circuit (s.C. Gnd or c.O.),

Potentiometer short circuited to vdc (potentiometer s.C vdc).

Dashboard: the error "exvl" (exhaust bypass valve) is shown on the service

display. The eobd warning ...

Check engine oil level

Check the engine oil level through the sight glass (1) on the right-hand side

of the oil sump.

Stop the engine and allow a few minutes for the oil to settle to a steady level.

Oil level must be checked with the vehicle perfectly upright and the engine

cold.

The oil must be between the m ...