Ducati Diavel Service Manual: Rectifier-regulator

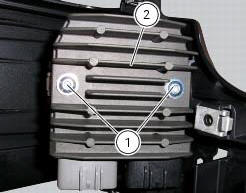

The rectifier (1) is placed in the electrical components compartment.

The rectifier/regulator consists of an aluminium casing containing the diodes that rectify the current produced by the alternator. It also contains an electronic device that regulates the current supplied by the alternator in accordance with battery voltage.

If the battery is drained, the current has the value necessary to restore optimum operating conditions of the battery. In contrast, if the battery is fully charged, the current value will be lower.

Note

Control the charger current by using the dds diagnosis instrument (sect. 6 - 11, Diagnostic instruments).

Removal of the regulator

Undo the two fixing screws (1) of the voltage regulator (2) and remove it together with them.

Important

Do not disconnect the battery cables when engine is running because this would cause irreparable damage to the regulator.

Refitting the regulator

Position the regulator (1) on the support.

Tighten the screws (1) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Important

Do not disconnect the battery cables when engine is running because this would cause irreparable damage to the regulator.

Regulator fuse

The 30 a fuse is located inside the solenoid starter in the electrical components compartment.

Remove the fuse cap (a) to reach it.

A blown fuse can be identified by breakage of the inner filament (b).

Important

To avoid possible short circuits, replace the fuse in key off condition.

Warning

Never use a fuse with a rating other than the specified value. Failure to observe this rule may damage the electric system or even cause fire.

Alternator

Alternator

It is equipped with a 12 v, 430 w generator, consisting of a fixed element

(stator, a) located on the generator cover and

of a movable element (rotor, b) fixed to the crankshaft.

Note

To chec ...

Electric starting system

Electric starting system

Note

The references of the elements listed below are those of the "wiring

diagram", sect. 6 -1.

Electric starting system

The key components of the electric starting system are a solenoid (6) and ...

Other materials:

Removal of the clutch master cylinder assembly

Warning

The clutch master cylinder manufacturer advises against servicing of

the clutch master cylinder (1) due to the safetycritical

nature of this component. Incorrect overhaul of this component could endanger

rider safety.

Maintenance operations of the master cylinder are limited to replac ...

Vehicle pre-delivery

Transport packaging integrity check (if required);

Removal from the transport packaging (if required);

Motorcycle integrity check;

Check of the supplied kit completeness (refer to the parts list supplied

together with the bike packaging);

Only if the bike is supplied in a crate: handle ...

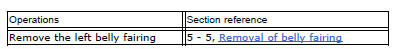

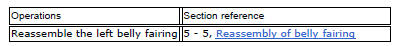

Reassembly of belly fairing

Position the oil cooler shield (7) inserting the tab (a) into the slit (b) in

the electrical components support (s).

Note

On refitting, make sure that the tab (c) remains positioned under the

retainers (d) of the shield (7).

Fit clips (11) on bracket (13) and orient them as shown in the f ...