Ducati Diavel Service Manual: Refitting the abs control unit

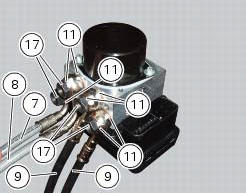

If the brake hoses (7), (8), (9) and (10) on the abs control unit are changed or removed, ensure that the fittings on the control unit are positioned correctly.

Warning

If incorrectly positioned, the hose can affect brake operation and foul moving parts. Position the hose as shown in the figure.

Pipes (7), (8), (9) and (10) fixing must be carried out by placing new gaskets (11) between the couplings.

Tighten the screws (17) to the torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Check that there are vibration dampers (22) and spacers (13) on the abs supporting bracket (12).

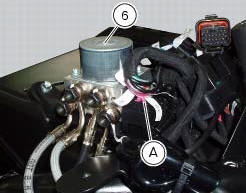

Refit the abs control unit (6) on the supporting bracket (12), and fix it by starting and tightening the retaining screws (16) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Connect the connector (a) of the abs control unit (6).

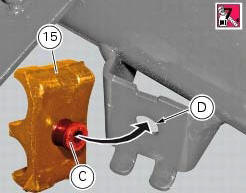

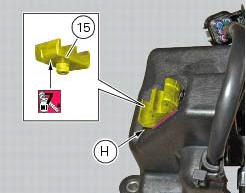

If removed, refit the front rubber pad (15) applying the recommended threadlocker to the pin (c) and the rear face of the pad. Fit the pad inserting pin (c) into the corresponding hole (d).

If removed, refit the rear rubber pad (15) applying the recommended threadlocker to the cover of the exhaust valve motor until achieving engagement.

Note

The rubber pad (15) must be aligned with the corresponding reference notch (h) as shown.

To fill up the system, carry out the instructions for replacement of fluid of the front and rear braking system master cylinder or calliper to which the pipe is connected (sect. 4 - 3, Changing the brake fluid).

Important

If the abs control unit is replaced, this must be supplied with secondary circuit already full of fluid; the control unit must Be fitted and the system filled and bleeded as a traditional system.

Removing of the abs control unit

Removing of the abs control unit

Drain the hydraulic fluid that is inside the front and rear braking system

tubes by disconnecting them from the master

cylinder and the calliper (sect. 4 -3, Changing the brake fluid).

Disco ...

Flexible wiring/hoses positioning

Flexible wiring/hoses positioning

The routing of the abs wiring has been optimised to ensure the minimum

obstruction.

Each section is designed to prevent interference with parts that might damage

wires or cause operating failur ...

Other materials:

Overhaul of the flywheel-alternator assembly

Examine the inner part of alternator rotor (24) for signs of damage. Check

that the starter clutch is working properly and

that the needle races do not show signs of wear or damage of any kind. If there

is any malfunction, remove the whole

assembly.

Disassembling the generator flywheel

U ...

Disassembly of the gearchange mechanism

Refer to the exploded view at the beginning of this section for indications

on disassembly and renewal of gearchange

components.

If the bushing (2) inside the pedal (1) needs replacing, grease the external

surface and drive the new bushing into place

using a press. The bushing must be seate ...

Final drive

Circlip

Nut

Washer

Nut

Rear sprocket flange

Cush drive bush

Inner ring

Chain

Spacer

Chain cover

Screw

Nut

Lock washer

Front sprocket

Spacer

O-ring

Rear sprocket

Spare parts catalogue

Diavel abs gearbox

Diavel abs rear wheel axle

Diavel carbon

abs

gearbo ...