Ducati Diavel Service Manual: Refitting the clutch master cylinder assembly

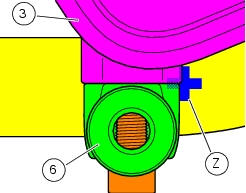

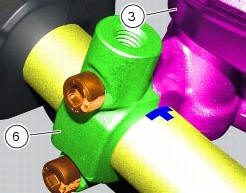

Insert the clutch master cylinder assembly (3) and the clamp (6) on the left handlebar, so that the top mating faces match the mark (z) on the handlebar as shown.

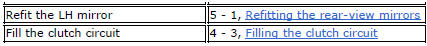

Couple terminal (6) to the clutch master cylinder control and fix them with the screws (v).

Tighten the retaining screws (v) to a torque of 10 nm +/- 10% (sect. 3 - 3, Frame torque settings) following the sequence 1-2-1 starting from the upper screw.

Locate the pipe (4) and seals (2) on the master cylinder assembly (3) and secure it with the special screw (1), without tightening it.

Warning

An incorrectly positioned hose can cause clutch faults and interfere with moving parts.

For the positioning of the clutch hose (4) and retaining clips, see the illustration at the end of this section.

Tighten the special screw (1) to the torque of 23 nm +/- 10% (sect. 3 - 3, Frame torque settings).

Removal of the clutch master cylinder assembly

Removal of the clutch master cylinder assembly

Warning

The clutch master cylinder manufacturer advises against servicing of

the clutch master cylinder (1) due to the safetycritical

nature of this component. Incorrect overhaul of this component ...

Removal of the clutch transmission unit

Removal of the clutch transmission unit

Warning

The manufacturer of the clutch transmission unit (15) advises

against servicing of its internal parts due to the safetycritical

nature of this component.

Incorrect overhaul of these cri ...

Other materials:

Throttle valve position sensor

Introduction

The throttle valve position sensor (tps) of the diavel is mounted on the

throttle body.

The sensor is integrated into the throttle valve actuator motor, which

turns the spindle of the vertical cylinder throttle

valve directly.

The sensor sends information to the engine con ...

Lap activation/deactivation function (lap time)

This function activates and deactivates the lap function (lap

time).

To access the function it is necessary to view the "setting" menu page 48, using

button (1, fig. 14) ?"

" or (2, fig. 14) ?" " select the "lap" function and

press the reset button

...

Specific operating strategies

Idle speed

No electric motor is used for idle speed regulation (bypass is modulated

instead with the throttle valve), as idle speed

control is effected by the ride-by-wire system. Idle speed is maintained by the

control unit when the speed drops below a

specific threshold and when the clutch ...